Case Study: Activated Charcoal Filter Structures Eliminate Odors, Emissions and Corrosion

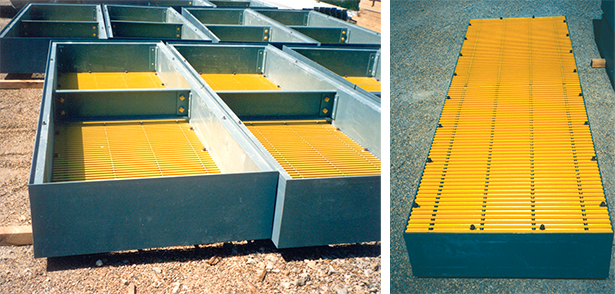

When the wastewater treatment plant in Milwaukee, Wisconsin is overloaded, wastewater effluent is pumped into tunnels to await treatment. The handling of gases, odors and vapors from this operation is very critical because tunnel openings are located near a hospital where air pollution control standards are very strict. The answer to the problem is a system of 288 fiberglass odor control structures that filter all air through activated charcoal.

When the wastewater treatment plant in Milwaukee, Wisconsin is overloaded, wastewater effluent is pumped into tunnels to await treatment. The handling of gases, odors and vapors from this operation is very critical because tunnel openings are located near a hospital where air pollution control standards are very strict. The answer to the problem is a system of 288 fiberglass odor control structures that filter all air through activated charcoal.

| TECHNICAL DATA |

|---|

| Product: Fiberglass Odor Control Structures |

| Process: Pultrusion |

| Materials: Fiberglass reinforced polyester, fire retardant |

Size: Custom rectangular tube:

DURAGRID® I-6000 1" Grating |

| For: HNTB Engineering |

| User: Milwaukee Metropolitan Sewage District |

A custom rectangular tube was designed for the frame of each odor control structure with a ledge on which the fiberglass grating panel is placed. Polypropylene mesh was attached to the grating to confine the activated charcoal between the two layers of grating and the frame. FIBREBOLT® fiberglass studs and nuts are used for the connections.

All materials were chosen for their corrosion resistance, as the odor control structures are exposed to sewer gases containing water vapor, hydrogen sulfide, methane, carbon dioxide, hydrocarbon gases, sulfuric acid and other acids.