Why Choose Fiberglass?

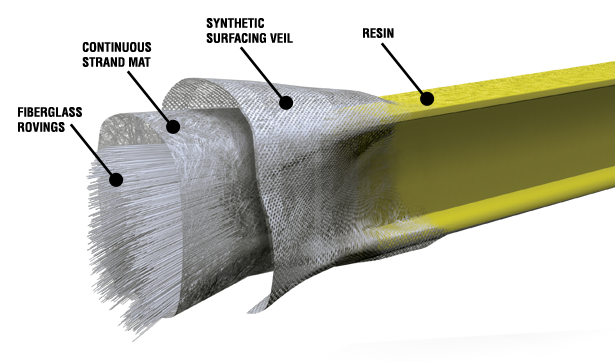

What is Fiberglass Reinforced Polymer?

Fiberglass Reinforced Polymer (FRP) is most often referred to simply as “fiberglass”. Used in this context, “fiberglass” is a composite consisting of a polymer resin matrix reinforced by embedded glass fibers. The strength of a fiberglass part is determined primarily by the type, orientation, quantity, and location of the glass fibers within the composite.

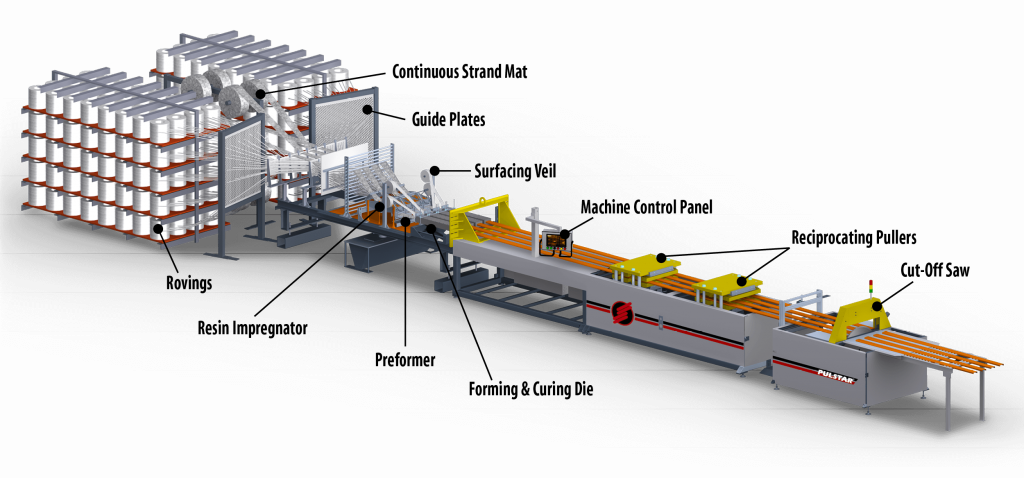

What is Pultrusion?

Pultrusion is a manufacturing process for producing continuous lengths of reinforced polymer structural shapes with a constant cross section. The process involves pulling the raw materials, a liquid resin mixture and reinforcing glass fibers through a heated steel forming die using a continuous pulling device.

The Features of Strongwell’s Fiberglass Composites

High Strength

Stronger than structural steel on a pound-for-pound basis. Used for building structures, walkways, platforms, etc.

Light Weight

Strongwell's fiberglass composite products weigh approximately 75-80% less than steel and 30% less than aluminum. This translates to lower transportation costs, easier installation and less weight in structural designs.

Corrosion Resistance

Strongwell’s proprietary “wet-out” process ensures complete reinforcement saturation. Fiberglass will not rot and is impervious to insects and a broad range of corrosive environments. Strongwell FRP composites have been successfully used for indoor and outdoor applications at hotels, restaurants, chemical plants, water and wastewater treatment plants, and in many other corrosive environments.

Low Conductivity

An excellent insulator, fiberglass has low thermal and electrical conductivity, making it a popular choice in electrical applications.

Electromagnetic Transparency

Fiberglass is transparent to radio waves, microwaves, and other electromagnetic frequencies. Strongwell composite products are regularly used in cellular applications due to this feature.

The Benefits of Strongwell’s Fiberglass

Reduced Maintenance Costs

Fiberglass corrosion resistance means that the need for routine painting and repair is virtually eliminated. Therefore, Strongwell's life cycle costs are often significantly lower than traditional materials.

No Heavy Lifting or Welding

Fiberglass is lightweight and may require less equipment, workers, and time to install. Additionally, fiberglass can be field fabricated with standard carpentry tools (using carbide or diamond blades). This translates to reduced risk of on-site injuries and downtimes associated with traditional materials and installation equipment.

Aesthetically Durable

Fiberglass products withstand weathering and intense use, providing long-lasting beauty. Once installed, Strongwell products are extremely low maintenance.

Safer for Employees

Fiberglass products are electrically non-conductive and can be manufactured with non-skid surfaces to provide a safe work environment for employees. For example, SAFRAIL™ fiberglass ladders and cages have been in use for more than 20 years and meet OSHA 1910.27 requirements.

Strongwell’s Quality Certifications

Strongwell is proud that many of its products bear the approval of numerous certifying agencies, including:

|  | |||||

|  |  | ||||

|  |  |