Why Choose Strongwell?

Strongwell Mission

To manufacture high quality pultruded fiber reinforced polymer composites and structures that solve problems and provide value for our customers, enable secure and desirable employment for our people, and create profits for future growth and development of our company.

Strongwell Vision

Adhering to our Guiding Principles and in an environment of high global awareness of the benefits of fiber reinforced polymers, Strongwell is the preferred supplier, best value producer, and leading innovator of pultruded composites and structures.

Strongwell Guiding Principles

- People Are Our Most Important Resource

- Safety is Paramount to Everything We Do

- Our Customers Are Our Focus

- Our Products Are Our Image

- Our Suppliers Are Our Partners

- Continuous Improvement Is The Key to Long Term Success

- Training Is The Foundation of Improvement

- Integrity Is Never Compromised

- Profits Are Essential

Financial Strength

Strongwell is debt-free and has a strong balance sheet. All property, plants, and equipment are owned (not leased). This financial strength provides the basis for Strongwell to stand behind its products, invest in R&D and innovation, invest in continuous improvement of all processes, and be a strong ally to suppliers and customers.

Experience

Strongwell manufactured its first pultruded products in 1956. In 1959, the Company produced its first ladder rail and has since produced over 1 billion feet of that product. The company was the first to develop a line of standard structural shapes (EXTREN®) and one of the first to offer pultruded grating in the 1970’s. Through the years, Strongwell has developed hundreds of other proprietary and custom products for many markets throughout the world. Each new product has contributed to the knowledge base that now goes into every Strongwell product. Strongwell has learned by performing, has a record of successful growth, and is recognized as the “gold standard” of pultruders. Its name and trade names are recognized worldwide.

Engineering Capability

Compared with other pultruders, Strongwell employs exceptional technical on-staff strength in all applicable engineering disciplines. The Company manufactures its pultrusion machinery, tooling, and dies, and hosts a full-service machine shop and chrome-plating operation in house. This translates to customers being able to work with Strongwell as a full-service provider for any pultrusion needs. Registered professional structural engineers design structures or provide technical design support to customers. Mechanical engineers design equipment, tooling, and perform FEA analysis on real or proposed pultruded parts. Electrical and systems engineers design the systems and electrical components that make the equipment efficient. Chemical engineers and chemists assure that the many resin systems used by Strongwell are right for the job. Graduate engineers also hold key positions in sales, manufacturing, quality assurance, and general management.

Size / Capacity

Strongwell has more than 65 pultrusion machines. These machines range from those capable of pultruding very large parts (for example a 36” double-webbed beam) to those capable of pultruding up to 40 lines at a time. The machines are housed in over 730,000 sq. ft. of manufacturing space in Strongwell’s four facilities. This strength in capacity allows Strongwell to supply any quantity of pultruded product a customer needs. It also provides flexibility to react quickly to meet tight schedules.

Product Range

Strongwell has by far the world’s largest array of proprietary fiber reinforced polymer (FRP) pultruded structural products including standard structural shapes, plate, grating, planking, handrail systems, building panels, ballistic resistant plate and systems, power poles, nuts and bolts, cooling tower components, ladder rail, and tool handles. The company also has hundreds of active customer-owned sets of dies and tooling for custom parts, some of which are available for use with a small royalty to the die owner. The extensive product range means more products to sell, and more products to choose to optimize solutions.

Fabrication Capability

Strongwell excels at fabrication from simple material preparation (sanding, cutting, routing, drilling, coping, and painting) to full assembly or pre-assembly. Experienced fabrication personnel make extensive use of CNC drills and routers and other computer controlled equipment to assure accuracy and efficiency. This capability becomes a de facto increase in an allied fabricator’s capacity and ability to deliver large volumes of fabricated products in a timely manner.

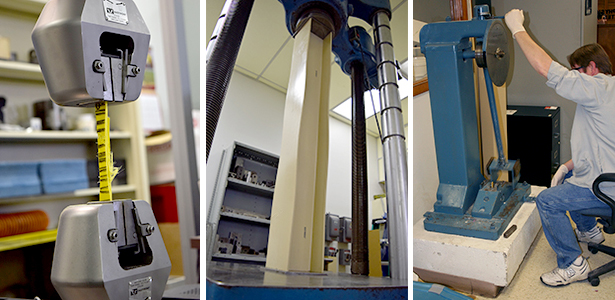

Quality and Testing

Strongwell has a 10,000 sq. ft. laboratory and R&D center in Bristol, Virginia and a smaller laboratory in Chatfield, Minnesota. Strongwell has in-house capability to perform most ASTM tests for pultrusion. The Company also takes advantage of the University of Tennessee and Virginia Tech, with their large composites testing capabilities, and supplier’s testing and R&D centers to supplement testing capability. Strongwell’s U.S. facilities are certified to ISO 9001 by DNV-GL. The company operates to strict procedures and protocols, and embraces the concepts of Total Quality Management (TQM) in all aspects of its business.

Research and Product Development

Strongwell has an active R&D and product/process development function. This results in a steady stream of:

- New products

- Product improvements

- Process improvements

- New materials for use in pultrusion

- Cost reductions

- New markets for composites

Strongwell is committed to the concept of continuous improvement.

Green Commitment

As a responsible corporate citizen, Strongwell continually seeks to improve its manufacturing practices to further protect the environment, while providing essential, environmentally friendly products to its customers. Strongwell works with universities and outside agencies to produce the data that will confirm pultruded composite products have a lower environmental impact and lower carbon footprint than competing structural materials like steel, aluminum, and concrete. “Green” policies and practices means that customers get an environmentally conscious supplier with documentation that can aide Strongwell customers in securing business with environmentally conscious end users.

Interactive Website

Strongwell’s website (www.strongwell.com) has many features and tools valuable to Strongwell customers. These include:

- A comprehensive Design Manual for Strongwell products

- Design guides for Strongwell special products and systems

- Downloadable Specifications

- Fabrication Worksheets

- CAD Blocks

- Corrosion Resistance Guide

- All Strongwell Product Literature

- Product Videos

- Case Studies

- Order tracking

- Online inventory

- Regulatory Compliance

Visitors can also register for Strongwell’s online training site. The website provides ready access to a wealth of information and tools regarding Strongwell products to aligned sellers and their customers.

Stability and Professionalism

Strongwell does not have frequent turnover in management or changes in strategic direction. It is not constantly “reinventing itself” or extending itself far beyond its core competency of pultrusion. Strongwell is a company with stable leadership and direction and has a well deserved reputation for honest, ethical, and common sense business practices. Strongwell leaders have the respect of their peers in pultrusion and the composites industry as evidenced by the numerous industry leadership positions currently and previously held by Strongwell management team personnel - far more than any other pultruder.

Made in the USA

All domestically-available Strongwell products are made exclusively in the USA to the highest standard of quality and appearance by workers who take pride in their work.