Structural Reinforcements

GRIDFORM™ Concrete Bridge Deck Reinforcements

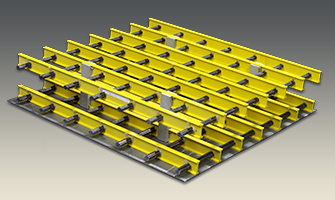

GRIDFORM™ is a prefabricated fiber reinforced polymer (FRP) double-layer grating, concrete-reinforcing system with integral stay-in-place (SIP) form for vehicular bridge decks.

GRIDFORM™ is a prefabricated fiber reinforced polymer (FRP) double-layer grating, concrete-reinforcing system with integral stay-in-place (SIP) form for vehicular bridge decks.

The system consists of FRP plates bonded to the bottom grating of FRP double-layer grating panels, creating a bidirectional, lightweight panel for the grid construction of corrosion-free concrete bridge decks.

The lightweight GRIDFORM™ panel, which weighs only 4.7 pounds per square foot, is shop-fabricated in very large units that are limited only by shipping constraints to approximately 50 ft. by 8 ft.

When the GRIDFORM™ arrives on site, it is lifted with a single pick of a crane and placed directly in the bridge girders. The GRIDFORM™ panel is pre-engineered and detailed to enable rapid attachment to the bridge girders and subsequent concrete placement and forming. The anticipated lifespan of a GRIDFORM™ bridge deck is several times that of steel reinforced concrete bridge decks since FRP provides a corrosion-free reinforcement system for the concrete.

When the GRIDFORM™ arrives on site, it is lifted with a single pick of a crane and placed directly in the bridge girders. The GRIDFORM™ panel is pre-engineered and detailed to enable rapid attachment to the bridge girders and subsequent concrete placement and forming. The anticipated lifespan of a GRIDFORM™ bridge deck is several times that of steel reinforced concrete bridge decks since FRP provides a corrosion-free reinforcement system for the concrete.

Designing with GRIDFORM™

Design of FRP-reinforced concrete bridge deck systems follows the methodology of AASHTO LRFD Bridge Design Specifications and ACI PRC-440.1 Guide for the Design and Construction of Structural Concrete Reinforced with Fiber-Reinforced Polymer Bars. Design assistance can be obtained by contacting Strongwell – Chatfield Location.

SAFSTRIP® Strengthening Strip

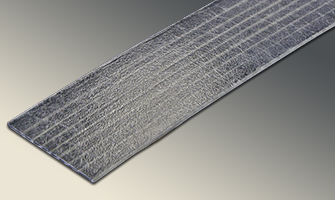

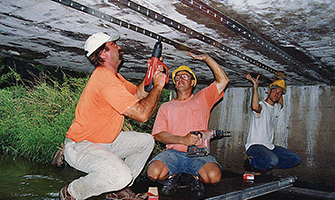

SAFSTRIP® is a pultruded composite strip that improves the strength of an existing structural member when mechanically fastened to the structure. The reinforcing strip has high bearing and longitudinal properties and is designed to strengthen the flexural capacity on the tension face of concrete girders, slabs and decks. Installation on bridges can occur without any interruption of service.

SAFSTRIP® is a pultruded composite strip that improves the strength of an existing structural member when mechanically fastened to the structure. The reinforcing strip has high bearing and longitudinal properties and is designed to strengthen the flexural capacity on the tension face of concrete girders, slabs and decks. Installation on bridges can occur without any interruption of service.

Low-Cost Rehabilitation with FRP Strips written by MARK D. WHITTEMORE, P.E., and ROBERT H. DURFEE, P.E., SECB DuBois & King, Inc., Bedford, New Hampshire as presented at the 2011 International Bridge Conference.

SAFSTRIP® is supplied in rolls and may be pre-drilled with holes at the required fastener spacing to receive fasteners. SAFSTRIP® measures 4" wide x 1/8" thick and is shipped in rolls up to 100 ft. long. SAFSTRIP® is designed to be easily field cut by the customer into shorter lengths using standard carpenter tools.

SAFSTRIP® is supplied in rolls and may be pre-drilled with holes at the required fastener spacing to receive fasteners. SAFSTRIP® measures 4" wide x 1/8" thick and is shipped in rolls up to 100 ft. long. SAFSTRIP® is designed to be easily field cut by the customer into shorter lengths using standard carpenter tools.

Features

- Easy to install, no skilled labor necessary

- Minimal surface preparation is needed for installation

- Structure is usable immediately after installation

- Cost effective system for increasing load capacity of bridges

- Will not split or delaminate when drilled

Engineering Design

The repair of concrete structures using SAFSTRIP® is dependent upon the concrete’s condition. The local engineer must determine the strength of the existing concrete. It must then be determined how much SAFSTRIP® is required and the spacing of fasteners.

Design of MF-FRP systems follows the methodology of ACI PRC-440.2: Design and Construction of Externally Bonded Fiber-Reinforced Polymer (FRP) Systems for Strengthening Concrete Structures. Design assistance can be obtained by contacting Strongwell – Chatfield Location.

SAFSTRIP® Carbon

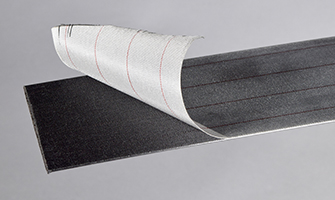

SAFSTRIP® Carbon is a unidirectional, carbon fiber reinforced polymer (CFRP) comprised of high tensile strength and high modulus carbon fibers encapsulated in a thermoset resin through the pultrusion process. SAFSTRIP® Carbon is designed to be used as an externally applied reinforcement for strengthening concrete, timber, and masonry structures. A peelply fabric is adhered to the plate that, when removed, leaves a prepared bonding surface for adhesion to a prepared substrate.

SAFSTRIP® Carbon is a unidirectional, carbon fiber reinforced polymer (CFRP) comprised of high tensile strength and high modulus carbon fibers encapsulated in a thermoset resin through the pultrusion process. SAFSTRIP® Carbon is designed to be used as an externally applied reinforcement for strengthening concrete, timber, and masonry structures. A peelply fabric is adhered to the plate that, when removed, leaves a prepared bonding surface for adhesion to a prepared substrate.

Typical Applications

- Structural Strengthening

- Seismic Strengthening

- Damage to Structural Parts

- Change in Structural System

- Design or Construction Defects

- Load Increases

- Serviceability Improvements