Case Study: Computer Testing Facility Constructed of DURASHIELD® Foam Core Panels & EXTREN®

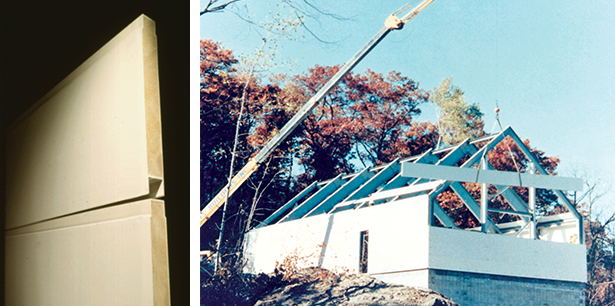

Designed to meet RFI/EMI codes (eliminates electromagnetic interference) for testing computer equipment, a 33' wide x 66' long x 24' high building of fiberglass was constructed in Rochester, Minnesota, for Amador Corporation. Construction used the 3" x 24" DURASHIELD® foam core panels, EXTREN® pultruded structural shapes, including a 24" I-beam and FIBREBOLT® fiberglass nuts and bolts. Amador conducts testing for computer equipment manufacturers in the facility. Its major customer at the facility is IBM.

Designed to meet RFI/EMI codes (eliminates electromagnetic interference) for testing computer equipment, a 33' wide x 66' long x 24' high building of fiberglass was constructed in Rochester, Minnesota, for Amador Corporation. Construction used the 3" x 24" DURASHIELD® foam core panels, EXTREN® pultruded structural shapes, including a 24" I-beam and FIBREBOLT® fiberglass nuts and bolts. Amador conducts testing for computer equipment manufacturers in the facility. Its major customer at the facility is IBM.

| TECHNICAL DATA |

|---|

| Product: All-Fiberglass Building |

| Process: Pultrusion |

Materials:

|

| Sizes: DURASHIELD® Panels: 3" thick x 24" wide EXTREN® structural shapes:

|

| For: Amador Corporation |

| User: IBM Corporation and other major computer companies |

Strongwell manufactures foam core building panels that are a tongue-and-groove design comprised of a pultruded skin with a 4 lb./ft.3 rigid, closed cell polyurethane foam core. The panels are available in 1" and 3" thick sizes. An excellent chemical and mechanical bond is achieved between the surface of the foam and the pultruded structure assuring long-term performance of the composite.

The pultruded skin is offered in flame retardant vinyl ester and polyester resin systems. A synthetic surfacing veil is incorporated into the surface of the skin to protect against weathering — ultraviolet (UV) and humidity — and corrosion resistance.

Foam core panels were selected over fiberglass corrugated panels because the foam core provided insulation in the cold Minnesota climate and was more attractive and easier to assemble.

Also the 3" thick panel provides more structural integrity than corrugated panels so the designer could eliminate extra reinforcements (purlins and girts) and still meet wind and snow load requirements of Minnesota building codes.