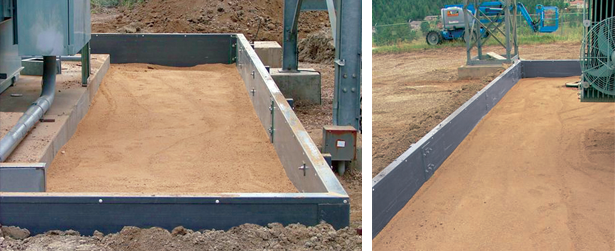

Case Study: Containment Success at Bergen Park in Denver

Chalk another one up for the time-saving COMPOSOLITE® Secondary Containment System! This type of containment is essential for substations. It is even mandated by the EPA because of the potential for oil leakage from transformers that may flow into adjacent bodies of water.

Chalk another one up for the time-saving COMPOSOLITE® Secondary Containment System! This type of containment is essential for substations. It is even mandated by the EPA because of the potential for oil leakage from transformers that may flow into adjacent bodies of water.

Several installations of these kits have proven extremely successful, including an installation at Xcel Energy’s Bergen Park substation in Evergreen, Colorado. The installation impressed the crew because of its easy and quick installation.

| TECHNICAL DATA |

|---|

| Product: Secondary Containment System |

| Process: Pultrusion |

Materials:

|

Sizes: EXTREN® structural shapes:

COMPOSOLITE® 24" x 3" panels |

| For: Xcel Energy's Bergen Park Denver, CO |

Vic Garcia of Pipe Valve and Fitting Company, a Strongwell distributor, visited the site and talked with the construction crew. They said the installation was “very slick.” The crews were delighted to use the FRP Secondary Containment System kit because it took them one day and only a few hours of the second day to install it. According to the crew, the same type of job in concrete would have taken them over a week to do!

It is proven that the COMPOSOLITE® Secondary Containment System exceeds the traditional concrete system benefits by being less costly – especially in remote areas – in addition to being easy to install!