Case Study: Fiberglass Beam Plays Supporting Role In Chrysler Minivans

The 1991 four-wheel drive Dodge Caravans and Plymouth Voyagers are equipped with durable, corrosion-resistant fiberglass pultruded beams that support a blow-molded polyethylene fuel tank. The fiberglass support beams keep the fuel tank from sagging in the hot, harsh environment of the under-vehicle area.

The 1991 four-wheel drive Dodge Caravans and Plymouth Voyagers are equipped with durable, corrosion-resistant fiberglass pultruded beams that support a blow-molded polyethylene fuel tank. The fiberglass support beams keep the fuel tank from sagging in the hot, harsh environment of the under-vehicle area.

The minivan's fuel tank covers a large portion of the undervehicle area. Extreme summer or desert temperatures — combined with heat from exhaust and emissions — could cause the span of the tank to sag. This concern over sagging led to the development of the fuel tank support beam.

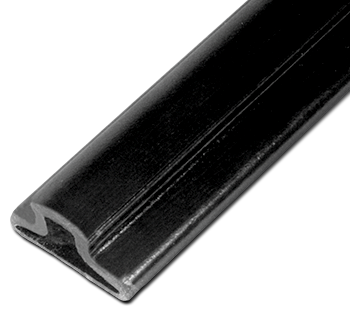

Each tank has two support beams perpendicular to the metal straps that hold the tank to the bottom of the vehicle. The beam has an integral flanged ridge that mates with a long slot molded into the bottom of the fuel tank. This design allows for quick and simple snap-fit assembly of the beam onto the tank.

| TECHNICAL DATA |

|---|

| Product: Fiberglass Fuel Tank Support Beam |

| Process: Pultrusion |

| Materials: Fiberglass reinforced isophthalic polyester |

| Properties: Excellent heat corrosion, impact resistance and high flexural properties |

| Size: 1" high x 1-1/2" wide x 26" long |

| Weight: .41 lbs./ft. |

| For: Solvay Automotive |

| User: Chrysler Corporation |

Manufactured of fiberglass reinforced isophthalic polyester with a surfacing veil, the support beam has excellent heat, corrosion and impact resistance and high flexural properties. This fiberglass beam is lighter than metal — an important consideration when looking for ways to offset the added weight of four-wheel drive. Fiberglass also resists corrosive attack from rain, snow and road salts.

Strongwell pultrudes the fiberglass beam in a continuous lineal profile, cuts the profile to 26" lengths and machines a minimal radius on each end to facilitate assembly and eliminate sharp edges.