Case Study: Fiberglass Cooler/Freezer Door Jamb Insulates and Saves Energy

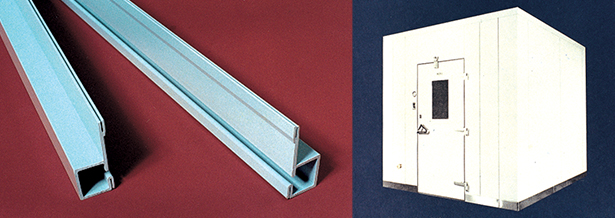

An efficient walk-in cooler/freezer requires a specially constructed door assembly to provide a tight seal without freezing up. Harford Systems Inc., in Aberdeen, Maryland, designed a door jamb assembly using a custom pultruded part chosen for strength, functional versatility and appearance.

An efficient walk-in cooler/freezer requires a specially constructed door assembly to provide a tight seal without freezing up. Harford Systems Inc., in Aberdeen, Maryland, designed a door jamb assembly using a custom pultruded part chosen for strength, functional versatility and appearance.

| TECHNICAL DATA |

|---|

| Product: Fiberglass Cooler/Freezer Door Jamb |

| Process: Pultrusion |

| Materials: Fiberglass reinforced polyester |

| Sizes: 4.0" (overall length) x 1.468" (overall width) x 2.172" (extension) x 0.125" (thick) |

| For: Harford Systems Inc. |

The heavy duty pultruded part provides a thermal barrier that eliminates a costly second heater circuit required on other low temperature doors. The thermally nonconductive pultruded door jamb is fitted with an anti-condensate heater circuit which goes around each door. Its resistance to heat flow means sweat-free cooler door openings — a real energy saver. The pultruded part is also strong, durable and corrosion resistant.