Case Study: Fiberglass Cover Puts a Lid on Air Pollution Problem at Oil Refinery

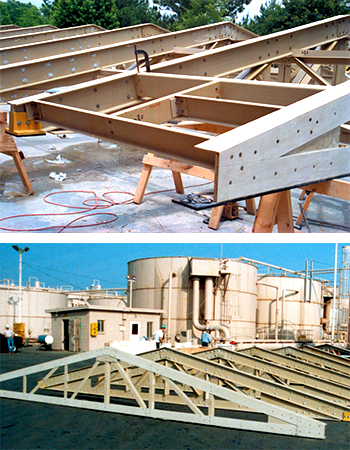

A 38'-4" long x 27'-8" wide x 5' high rectangular all-fiberglass cover was designed, fabricated and installed by Strongwell to cover and contain fumes in a sulfur pit at a Shell Oil Production Unit

A 38'-4" long x 27'-8" wide x 5' high rectangular all-fiberglass cover was designed, fabricated and installed by Strongwell to cover and contain fumes in a sulfur pit at a Shell Oil Production Unit

in Huntington Beach, California. The previous cover of carbon coated steel failed because of corrosion. Leaking fumes also were an air pollution problem.

The challenge was to design, fabricate and install a vapor-tight cover to contain hydrocarbon emissions. The cover had to be capable of withstanding 1.0 psi pressure, 0.5 psi suction and meet UBC Zone 4 (earthquake zone building codes), assuring the customer that the cover would meet Air Pollution Control Regulations over the long run.

| TECHNICAL DATA |

|---|

| Product: Fiberglass Sulfur Pit Cover |

| Process: Pultrusion |

| Materials: EXTREN® Series 625 fiberglass reinforced vinyl ester, fire retardant |

Sizes: EXTREN® structural shapes:

|

| For: Shell Oil |

The superstructure of the cover is comprised of pultruded fiberglass/vinyl ester structural shapes. The roof panels are constructed of 1/8" thick fiberglass plate skins that are subsequently filled with foam. Neoprene gaskets and flanges are used to make the cover vapor-tight.

The FRP cover was field assembled adjacent to the pit, then lifted into place in one piece. The single lift of 10,000 lbs. was accomplished with FRP lifting trusses and pad eyes integrally designed into the cover superstructure.