Case Study: Fiberglass Cover puts a Lid on Corrosion Issues

The annual direct cost of corrosion, according to NACE International, is $276 billion, or approximately 3.1% of the U.S. Gross Domestic Product (GDP). Although corrosion is an expected process, it is possible to control by utilizing proper building materials/engineering for each sector. In wastewater and potable water systems, the annual cost of corrosion is attributed to $48 billion annually or 35% of overall total corrosion related costs in that industry.

The annual direct cost of corrosion, according to NACE International, is $276 billion, or approximately 3.1% of the U.S. Gross Domestic Product (GDP). Although corrosion is an expected process, it is possible to control by utilizing proper building materials/engineering for each sector. In wastewater and potable water systems, the annual cost of corrosion is attributed to $48 billion annually or 35% of overall total corrosion related costs in that industry.

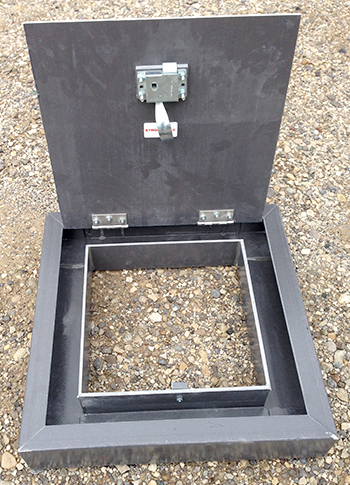

With that in mind, Doug and Dan Todd from Infinite Composites designed and fabricated all-fiberglass covers and access hatches to contain harmful fumes and greenhouse gases such as sulphuric acid, methane gas, nitrous oxide, and carbon dioxide. Traditional covers are manufactured using painted aluminum or galvanized steel. Both weight and corrosion issues caused these hatches to fail through the leakage of corrosive and harmful fumes which attribute to air pollution and nuisance issues.

| TECHNICAL DATA |

|---|

| Product: Fiberglass Access Hatch |

| Process: Pultrusion |

| Materials: EXTREN® Series 525 structural shapes and plate |

Sizes:

|

| For: Infinite Composites |

The challenge by Infinite Composites was to design, fabricate and install a tight-fitted cover to contain harmful emissions and odors. The covers also must be capable of meeting or exceeding the various mechanical performance standards set by the aluminum or galvanized steel counterparts.

These hatches are comprised of pultruded fiberglass/polyester EXTREN® Series 525 structural shapes. Mechanical and epoxy based connections were utilized in this design to provide years of lightweight, corrosion-free operation. Each FRP hatch can be prefabricated or assembled on site, virtually eliminating the need for welding or specialty tools.