Case Study: Fiberglass Handrail System Reduces Time for Chicago Transit

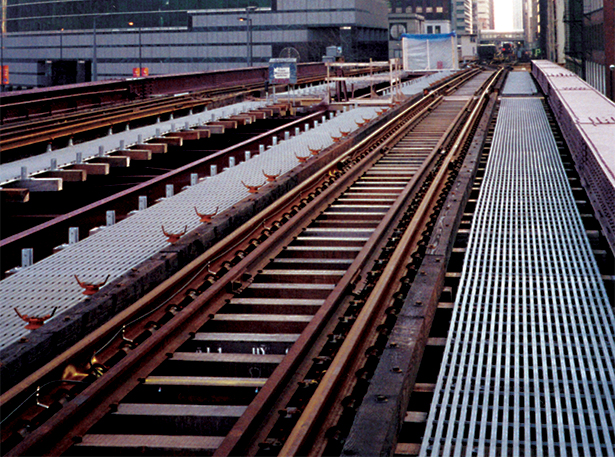

The Chicago Transit Authority’s (CTA) modernization project is the largest single fiberglass fabricated project in the United States and possibly the world. The CTA chose to improve worker safety and cut maintenance costs by replacing wooden worker walkways and emergency escape routes beside elevated train tracks with DURADEK® fiberglass grating and SAFRAIL™ fiberglass handrail. With over 70,000 lineal feet of fiberglass handrail, 70,000 lineal feet of fiberglass structural beams, 430,000 square feet of fiberglass grating and over 100,000 hold down clips, you can imagine how large this job really was. The installation was clearly a major achievement for the industry and exemplifies the overall acceptance and use of composite materials.

The Chicago Transit Authority’s (CTA) modernization project is the largest single fiberglass fabricated project in the United States and possibly the world. The CTA chose to improve worker safety and cut maintenance costs by replacing wooden worker walkways and emergency escape routes beside elevated train tracks with DURADEK® fiberglass grating and SAFRAIL™ fiberglass handrail. With over 70,000 lineal feet of fiberglass handrail, 70,000 lineal feet of fiberglass structural beams, 430,000 square feet of fiberglass grating and over 100,000 hold down clips, you can imagine how large this job really was. The installation was clearly a major achievement for the industry and exemplifies the overall acceptance and use of composite materials.

An alternate post design for the SAFRAIL™ fiberglass handrail system, developed for the Chicago Transit Authority, drastically reduced the installation time normally required. The new 2 3/8" x 3/16" handrail post was prefabricated by cutting back the top rail section and routing a square hole for the mid-rail. The top and mid rails were quickly and easily riveted into place in the field. The posts were then inserted into the top mounted base plates (prefabricated galvanized stanchions).

| TECHNICAL DATA |

|---|

| Product: Transit Worker Walkways and Handrail |

| Process: Pultrusion, Fiberglass Fabrication |

Materials:

|

Sizes:

|

| For: Chicago Transit Authority |

Fiberglass structural beams were mounted onto the wooden cross-tie beams to support FRP walkway grating. The fiberglass walkways and worker platforms replaced wooden structures which had warped and deteriorated from the weather. DURADEK® T5000 2" grating was selected to reduce maintenance and improve worker safety. In addition to the anti-skid grit surface on the grating, the inherent non-conductivity of fiberglass makes it safer to work around the electrically operated transit rails.

The fiberglass walkway systems will not require the constant maintenance of the wooden structures and are expected to last at least twice as long.