Case Study: Fiberglass Highlights the Lines of Safety

Workplaces and places of businesses adhere to the emergency planning protocol of at least two exit routes to comply with safety exit standards. This ensures that alternate routes are available for the evacuation of employees and other occupants in the event of an emergency.

In large industrial settings, the quantity of available exit routes becomes dependent on the number of employees, building size, and floorplans.

As a best practice approach to clearly identify exit routes, the use of cautionary paint, lighting, or clear labeling is encouraged to identify escape routes.

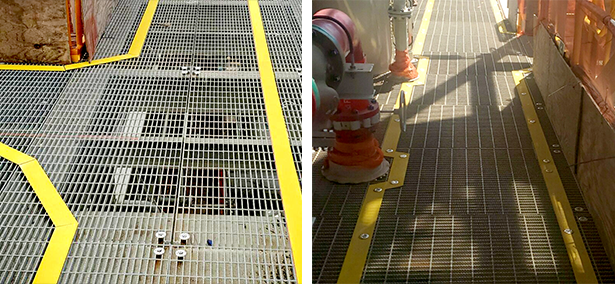

In this particular case study, Strongwell’s custom phenolic plate was integrated within a steel grating flooring system on an offshore hydrocarbon extraction rig. The end user needed a solution to clearly highlight an egress walkway that also serves as one of many escape/exit routes. The initial approach was to apply industrial safety yellow paint to the steel grating. As this was an exterior walkway, concerns regarding paint adhesion, durability, reapplication, and fading required a more robust and long-lasting solution.

| TECHNICAL DATA |

|---|

| Product: Custom Phenolic Satety Strip |

| Process: Pultrusion |

| Materials & Sizes: Phenolic Strip:

|

| User: Offshore hydrocarbon extraction rig |

The installer decided to utilize composites. Multiple pieces of 1/8" x 4" x 120" narrow phenolic sections of pultruded fiberglass were coated with safety yellow paint and treated with a urethane coating. As an added anti-slip safety measure, the plate was also treated with a surface grit coating to ensure multiple years of maintenance-free service dedicated to cautionary safety.

Once delivered, the installers were able to fabricate to size and mechanically attach the narrow plates to the steel grating via Hilti hold downs.

Upon completion, the end user and installer were both impressed by the overall ease of fabrication and assembly of these safety markers.