Case Study: Fiberglass Whale Lift Performs Under Pressure

Shamu and other killer whales perform daily at Sea World. Keeping these star performers healthy and happy is a major concern for all theme parks.

Shamu and other killer whales perform daily at Sea World. Keeping these star performers healthy and happy is a major concern for all theme parks.

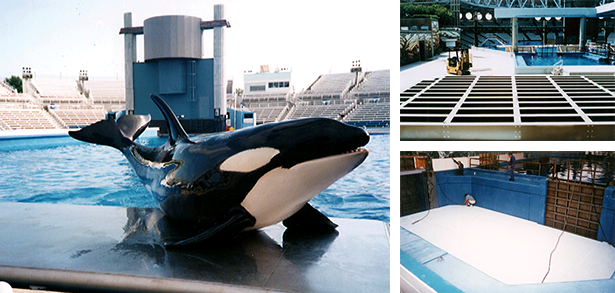

EXTREN® fiberglass structural shapes form the framework for a fiberglass whale lift designed to raise the killer whales out of the water quickly for medical exams. Designed to lift up to 85,000 pounds, the structure will support one or two whales along with a staff of people and may even include equipment such as an x-ray machine. Prior to these lifts, the tanks had to be fully drained to get to the animals. This procedure took up to as long as an hour and traumatized the animals.

The fiberglass lift platform measured 25' x 40' and used the EXTREN® 24" I-beam for the main frame. It was covered with a decking of corrosion resistant DURAGRID® T-1000 1" grating. The fabricated structure weighs approximately 13,600 pounds. It is submerged in a retaining pool where the platform can be raised or lowered by a water-hydraulic system which uses no oils or fluids to prevent contaminating the water.

| TECHNICAL DATA |

|---|

| Product: Fiberglass Whale Lift |

| Process: Pultrusion, Fiberglass Fabrication |

| Materials: Fiberglass reinforced polyester EXTREN® Series 500 structural shapes DURAGRID® T-1000 1" grating SAFPLATE® fiberglass gritted plate |

| For: Sea World |

Robin Friday, Curator of Animal Training with Sea World, was instrumental in the design and implementation of this lift which has been adopted by other zoos and theme parks throughout the country.

The performance platform shown below is also fabricated from fiberglass. Corrosion resistant SAFPLATE® provides a structurally sound and safe landing for Shamu.