Case Study: Future Maintenance Problems Eliminated with Fiberglass Structures

The Pump station in Des Moines, Iowa was built to handle excess sanitary and storm sewer loads. When Des Moines gets heavy rains and the Municipal Wastewater Treatment Plant becomes filled to capacity, the excess sanitary and storm sewers are diverted to lagoons in the southern sections of Des Moines. After a period of time the water is pumped out of these lagoons back to the municipal plant.

The Pump station in Des Moines, Iowa was built to handle excess sanitary and storm sewer loads. When Des Moines gets heavy rains and the Municipal Wastewater Treatment Plant becomes filled to capacity, the excess sanitary and storm sewers are diverted to lagoons in the southern sections of Des Moines. After a period of time the water is pumped out of these lagoons back to the municipal plant.

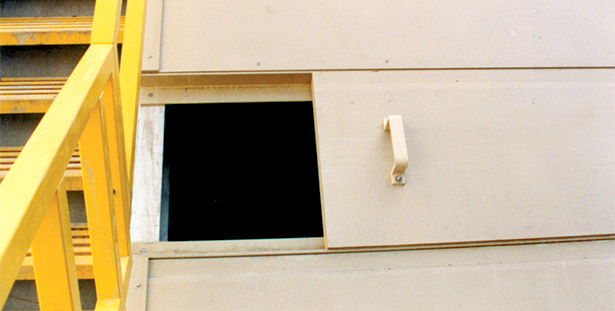

The pump station houses two large screw pump augers, 45' long, with another section the same size for future use. These screw pump augers are covered with 3" DURASHIELD® Series 625 panels. Each 45' long screw pump auger covering has six sections that can be slid out for access to the screw auger. Corrosion resistance, weight savings and insulation qualities were of great benefit in this application. Because of these benefits, the engineer also used 1" DURASHIELD® Series 625 panels to cover the outside walls of the pump house basement.

| TECHNICAL DATA |

|---|

| Product: Screw Pump Auger Covers Fiberglass Walkways, Handrail, and Worker Platforms |

| Process: Pultrusion, Fiberglass Fabrication |

Materials: Fiberglass reinforced vinyl ester, fire retardant:

|

Sizes:

|

| For: City of Des Moines, Iowa |

Handrail/walkway systems, stairway systems, worker platforms and floor areas surrounding equipment are yellow DURADEK®, and SAFRAIL™ fiberglass materials, pultruded and fabricated at Strongwell-Chatfield Location.

This pump station is one of several projects in the Des Moines Wastewater Treatment System which have used fiberglass products manufactured by Strongwell. Previous projects included media trickling filters of DURAGRID® grating and other fiberglass walkways and worker platforms that have given trouble-free service for several years. Veenstra & Kimm, Inc. of Des Moines were the engineers on this project and selected Strongwell fiberglass materials because they are corrosion resistant, maintenance free and easy to install. In addition, Strongwell offered design assistance, reliable fabrication, and efficient service.