Case Study: Modular Plant Growth Chambers

As the agricultural sector continues to venture into models of sustainable farming, so have the developments to evolve beyond the usage and reliance of greenhouses. New materials and technologies have allowed farmers, entrepreneurs, and startups to harness controlled-environment agriculture.

As an early adopter of FRP, SEED International, Inc., sought out commercial and housing applications to incorporate fiberglass into distressed or remote locations. As they considered new applications for fiberglass, they realized that composites could be used to create opportunities with the development of plant growth chambers in topographically difficult or climate challenged areas.

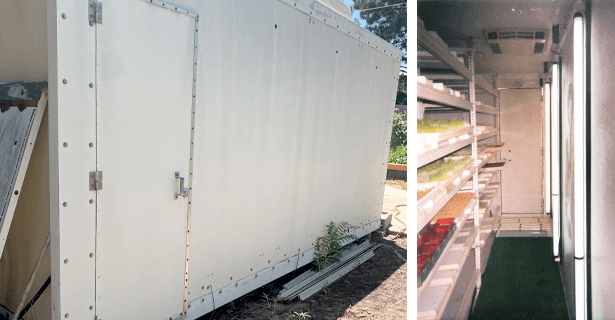

Designed to resemble a functioning sealed ecosystem, the modular systems are self-contained units that can be installed above or below ground. Their smaller footprint allows them to be utilized with traditional or renewable energy hookups.

| TECHNICAL DATA |

|---|

| Product: Modular Plant Growth Chambers |

| Process: Pultrusion, Fabrication |

Materials & Sizes:

|

| For: SEED International, Inc. |

| User: Certified Organic Vegetable Farm |

SEED International produced two versions of these food production chambers to a certified organic vegetable farm. The end user needed modularity and ease of transport to and from different farming sites.

Each production chamber was designed with an assortment of FRP products to ensure overall dry weight reduction for ease of transport. Below are a few highlights of how Strongwell’s products were used within the chamber:

- To ensure ease of access, minimal weight, and maximum corrosion resistance, FRP was chosen in lieu of metallic options for the door.

- DURADEK® pultruded grating was used for a shelving system to ensure durability and maximum drainage during growing and cleaning cycles.

- EXTREN® channels and angles were used as housing for lighting sources, water collection culverts, and diversion support structures.

The design and overall end product was well received and placed into the field of service for many years.