Case Study: Pultruded Rods and Nuts Support HVAC Ductwork in Aquatic Environments

Year-round indoor waterparks continue to push the envelope for innovative design to entertain guests and meet needs. The aquatic industry also must provide a healthy, safe, and inviting environment for indoor swimming and recreation. Especially important in indoor aquatic environments, the multiple air exchange standards, set by ASHRAE (American Society of Heating, Refrigerating, and Air Conditioning Engineers), offer the guidelines for regulating the quality of air, water, humidity, ventilation, and chemistry. These standards have greatly expanded the implementation of complex ventilation and high-end HVAC systems in indoor waterparks.

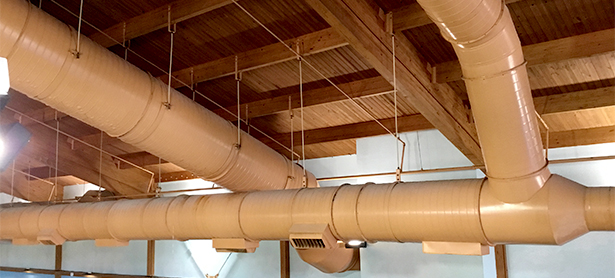

Currently, Michigan’s largest indoor waterpark measures 50,000 square feet and contains waterslides, raft rides, a lazy river, action river, sports pools, wading pools and other assorted features. The operators of the facility needed to replace stainless steel threaded rods which supported their state of the art HVAC ductwork system. Over time, the rods had corroded beyond repair and needed to be replaced prior to becoming a safety hazard. Although a simple and common method for hanging such ductwork, in an indoor waterpark, the stainless rods were simply no match for the environment. Over time, all metals will corrode due to elevated levels of humidity, evaporation, contact gases, ventilation, and temperature.

| TECHNICAL DATA |

|---|

| Product: HVAC Ductwork Support Rods and Nuts |

| Process: Pultrusion |

| Materials & Sizes: FIBREBOLT® Studs & Nuts |

| User: Michigan's largest indoor waterpark |

The park, with the aid of Strongwell’s Corrosion Resistance Guide and its portfolio of detailed aquatic fiberglass applications, decided that pultruded fiberglass FRP threaded rods were the best material option to replace the corroded stainless steel rods supporting the aquatic center’s network of ducts and vents. The threaded rods were attached to support pillars and ductwork utilizing FIBREBOLT® studs and nuts to minimize metallic exposure.

Overall, the end user has been pleased with the product, ease of installation, and the projected decades’ worth of performance from pultruded fiberglass rods.