Case Study: Raised Floor Features Corrosion Resistance and Design Flexibility

Pacific Video, one of the largest film development laboratories in Hollywood, California, required a raised floor system for their processing room. The floor system was needed to surround existing equipment, provide access above and below the floor, withstand a corrosive environment and provide 100 lbs. per square foot load capacity for future equipment installations.

Pacific Video, one of the largest film development laboratories in Hollywood, California, required a raised floor system for their processing room. The floor system was needed to surround existing equipment, provide access above and below the floor, withstand a corrosive environment and provide 100 lbs. per square foot load capacity for future equipment installations.

| TECHNICAL DATA |

|---|

| Product: Raised Floor System |

| Process: Pultrusion |

Materials:

|

Sizes:

|

| For: J.T. Ryerson & Son, Vernon, CA |

| User: Pacific Video |

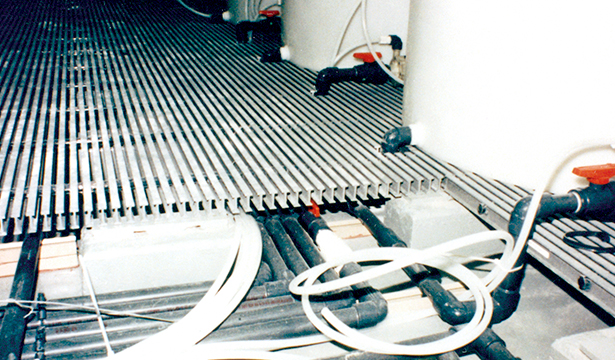

Working through their distributor, J. T. Ryerson & Son of Vernon, CA, Strongwell designed and prefabricated a 42" high raised floor system that enabled process workers to reach the top of machines and gave maintenance workers access to electrical equipment and piping below. The 525 square foot fiberglass floor was constructed of raised floor interior cross columns, fiberglass foam core planks, and 2" x 1/8" square tubes used for bracing members. This superstructure topped with DURAGRID® stair treads and EXTREN® 2" x 2" x 1/4" handrail, are located at each end of the floor. One stairway is hidden below the floor for a fire escape route.

Pacific Video already had structures of EXTREN® and DURAGRID® grating in the plant and knew that fiberglass was ideal for this application because it is nonconductive and noncorrosive. Circulating vapors of caustic bleach, sulfuric acid and sodium thiocyanate are constant corrosion problems and the large amount of electrical equipment used in the plant is a safety concern. Floors in other processing rooms are sloped concrete, which are slippery when wet. The non-skid grit surface of the DURAGRID® grating enhances worker safety.