Case Study: SAFSTRIP® Offers Underground Support

Below a multi-story apartment complex in Ontario, Canada, resides an underground parking garage which recently underwent a concrete support renovation.

Located within a high-density neighborhood, the complex is dependent on the parking garage for its residents, so long-term parking disruptions were not an option for this support renovation.

After the owners and engineers evaluated the condition of the concrete, Antonio’s Excavating and General Contracting worked on the logistics of installing SAFSTRIP®, spacing of fasteners, equipment placement, and surface preparation.

As a pultruded composite, SAFSTRIP® has high bearing and longitudinal properties and is designed to strengthen the flexural capacity on the tension face of concrete girders, slabs, and decks. While being drilled during installation, SAFSTRIP® will not split or delaminate due to its composite design.

SAFSTRIP® design is unique for a composite because it was initially designed with the support of the U.S. Army Engineer Research and Development Center and the University of Wisconsin Structures and Materials Testing Laboratory. Market pressures demanded an efficient process to increase the load capacity of individual bridges through the use of a mechanically-fastened fiber reinforced polymer (MF-FRP).

| TECHNICAL DATA |

|---|

| Product: Parking Garage Support Strengthening Strip |

| Process: Pultrusion |

Materials & Sizes:

|

| Installer: Antonio's Excavating and General Contracting |

| User: Ontario, Canada apartment complex |

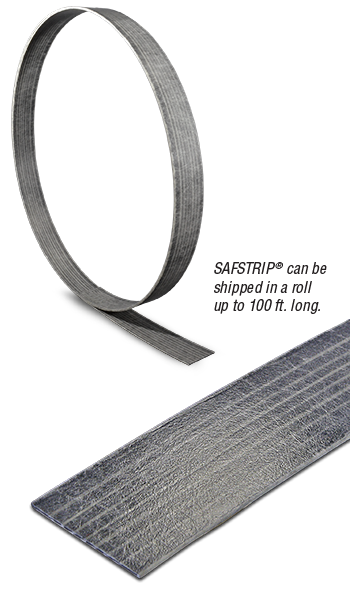

For portability, SAFSTRIP® can be shipped in rolls up to 100 ft. in length. This ensures that installers have greater flexibility in cutting pieces to exact length in the field.

With the parking garage having only six feet of height clearance, both the installers and customer were impressed at how quickly and easily SAFSTRIP® was installed with a small team and minimal onsite equipment. This renovation provided the necessary improvements to the concrete structure allowing many additional years of service before a full restoration will be required.