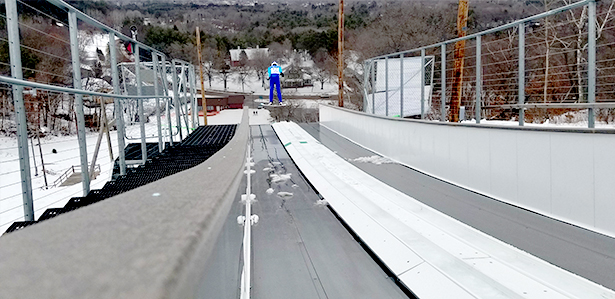

Case Study: Ski Jump Lands Well with Composites

Located in Eau Claire, Wisconsin, the Flying Eagles Ski Club has been in operation for well over a century to promote recreational and competitive levels of skiing and ski jumping.

The facility recently unveiled a new and improved 55-meter ski jump to replace its wooden 40-meter predecessor. In designing its new cantilevered structure, the owners needed it to easily withstand the high winds and frigid winters common in Wisconsin. This feat was achieved through engineering with an impressive combination of steel, concrete, and composites. Over a period of three years, the project was designed, shipped, and installed for competition use.

Outfitted with two types of fiber reinforced polymers, the new ski jump uses Strongwell’s SAFDECK® overlapping decking panels within the inrun track portion of the structure and DURAGRATE® molded grating and stair treads within the skier access and walking areas. Both products were manufactured with polyester fire-retardant resins. To aid in long term slip resistance, an epoxy grit surface was applied on the molded grating.

In addressing why FRP was used, the engineer noted that much of the superstructure uses galvanized cold formed steel. This eliminated the use of preservative treated lumber as most wood sold in the marketplace today can corrode steel. Structural FRP was sourced due to its inert nature and compatibility with galvanized steel.

| TECHNICAL DATA |

|---|

| Product: Ski Jump Stair Treads and Inrun Decking |

| Process: Molded, Pultrusion |

Materials & Sizes:

|

| For & User: Flying Eagles Ski Club |

In the previous wooden ski jump structure, maintenance concerns arose from the constant thermal cycling of wood. The introduction of FRP virtually eliminated all those concerns as FRP is dimensionally stable.

As is common with ski jumps, operations in the winter encourage ice build up throughout the structure. Tradeoffs with the previous wooden structure meant excessive snow buildup, leading to the creation of slip hazards. With the use of gritted DURAGRATE® molded gratings, the designed openings allow snow to melt or disperse through the material.

Following up on the installation, the Flying Eagles Ski Club was extremely pleased with the ease of the installation. Multiple workers were able to easily collect and transport the lightweight FRP components via stairs for final placement. The ski club also commented on how the pultruded products met their expectations with regards to added traction and ease of snow removal.