Case Study: Wet-Dry Lift Station Access Ladders

The processing of blackwater and greywater discharges are reliant on key infrastructure instruments within any municipality. To address changes in elevation, water discharges from households and businesses are heavily dependent on the role and strategic locations of lift stations within their respective communities.

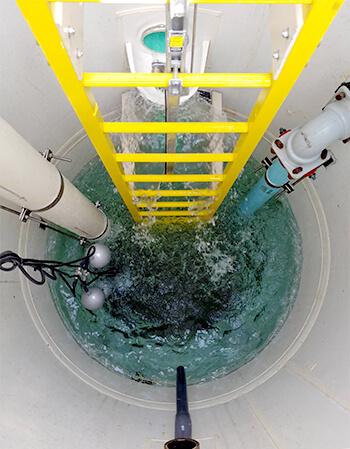

Although all lift stations complete an identical task, their individual engineering and designs can vary due to the demands of their workloads. Each lift station is typically outfitted with a receiving well, pumps, piping, motors, power supply, alarm system, and an odor control system.

Romtec Utilities, Inc., an engineering company specializing in the design, engineering, and supply of pumping systems across all water types, worked with the Northshore Utility District to design a site-specific lift station for its medium water support needs in a residential community.

| TECHNICAL DATA |

|---|

| Product: Wet-Dry Lift Station Access Ladders |

| Process: Pultrusion, Fabrication |

Materials & Sizes:

|

| For: Romtec Utilities, Inc. |

| User: Northshore Utility District |

With durability in mind, engineers wanted the material that had the highest corrosion resistance in the marketplace due to the presence of corrosive offset gases emitted through the movement of wastewater.

For the wet well portion, an 11' section of SAFRAIL™ ladder was used to ensure decades of maintenance access to essential pump valves and critical equipment. The nonconductive and corrosion resistant product was an easy decision versus coated or uncoated metallic options.

Manufactured by Strongwell in the USA since the 1950s, fiberglass ladders have demonstrated outstanding durability in complete fluid immersion applications versus steel and aluminum.

Since the date of original placement into service in 2018, both the end-user and installer have been pleased with how the overall product has performed in the field.