4 Ways to Customize Your Fiber Reinforced Polymer

Pultrusion is a leading technique for manufacturing custom fiber reinforced polymer structures. High-strength textiles are reinforced with multiple bonding agents and formed into bespoke shapes to meet specific customer requirements. This method represents an outstanding range of customizable options, from the component’s shape and size profile to the bonding materials used to enhance its aesthetic or mechanical properties.

Reinforcements

In pultrusion, continuous lengths of a textile material are fed through a performer and treated with a bonding resin that can be specialized for specific industry requirements. The first step in customizing your fiber reinforced polymer material is deciding upon the type, form, and placement of reinforcements required for the end-product. These can include multi-filament carbon fiber strands and fiberglass mats. There are countless combinations available for reinforcing custom fiberglass structures.

Shape & Size

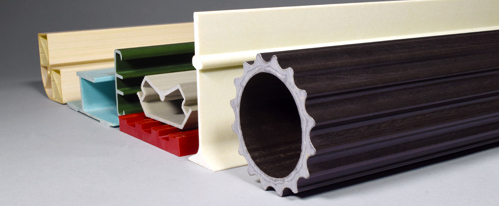

One of the primary benefits of pultruded fiber reinforced polymers are their versatility in terms of shape and dimensions. It is possible to fabricate large or small, thick or thin, simple or complex components in practically any shape with a constant cross-section. The size ranges of individual components vary from a ¼” circuit board stiffener to a 36”x18” double web beam. The complexity of these designs can be finely tailored to application-specific requirements.

Resin Matrix

Standard resins include polyesters and vinyl esters, which are designed to enhance the strength and corrosion-resistant properties of the product. More complex thermosetting polymers, such as phenolic resins, are available for fiber reinforced polymer products with improved thermodynamic stability. The resin matrix used in fiberglass pultrusion can provide superior impact resistances, flame retardancy, and a range of aesthetic options.

Colors

Unlike conventional materials that need to be painted or coated with inks and varnishes, fiber reinforced polymers can be fabricated with colors integrated into the product’s resin matrix. These pigmented resins provide a selection of design options that are intrinsically resistant to gradual aesthetic degradation. Additional surface media can be overlaid as a protective topcoat, including inset graphics or text.

Custom Fiber Reinforced Polymers with Strongwell

At Strongwell, our goal is finding a unique material solution for every application. Our custom pultrusions have been used to construct components for an array of demanding industries, including the construction of wind turbine blades, helicopter windshield posts, fuel tank support beams, and many more.

Read How is Industrial Fiberglass Manufactured? if you would like to learn more. Or, contact us if you have a design idea that can only be achieved with custom fiber reinforced polymers.