ASCE 7 Standard FRP Products

Integral to building regulations in the US, ASCE 7 standards underline the day-to-day practices of professionals involved in the construction, alteration, or maintenance of structures. This encompasses the work of architects, structural engineers, and materials suppliers alike. The expansive document provides a robust framework for ensuring that structures, and all their component parts, are designed to safely support factored loads and load combinations.

The American Society of Civil Engineers (ASCE) was first established in 1852, long before the commercialization of fiber-reinforced polymers (FRP) and other composite materials. However, the increasing uptake of fiberglass composites in architectural and structural applications brings many FRP products firmly under the jurisdiction of ASCE 7.

The American Society of Civil Engineers (ASCE) was first established in 1852, long before the commercialization of fiber-reinforced polymers (FRP) and other composite materials. However, the increasing uptake of fiberglass composites in architectural and structural applications brings many FRP products firmly under the jurisdiction of ASCE 7.

At Strongwell, we engineer all our architectural solutions with ASCE 7 compliance in mind. This is defined in section 1.3.1 of the Minimum Design Loads for Buildings and Other Structures:

“Buildings and other structures, and all parts thereof, shall be designed and constructed to support safely the factored loads in load combinations… without exceeding the appropriate strength limit states for the materials of construction.”

Overview of Design Loads in ASCE 7

ASCE 7 codes provide technical engineering guidelines for ensuring the safety and stability of structures in response to application-specific load combinations. This comes in the form of easily-accessible hazard data and risk mapping relevant to common load factors in real-world environments. These include atmospheric ice, earthquake, flood, rain, snow, soil, tsunami, and wind loads. Both dead and live loads are also covered by ASCE 7 standards.

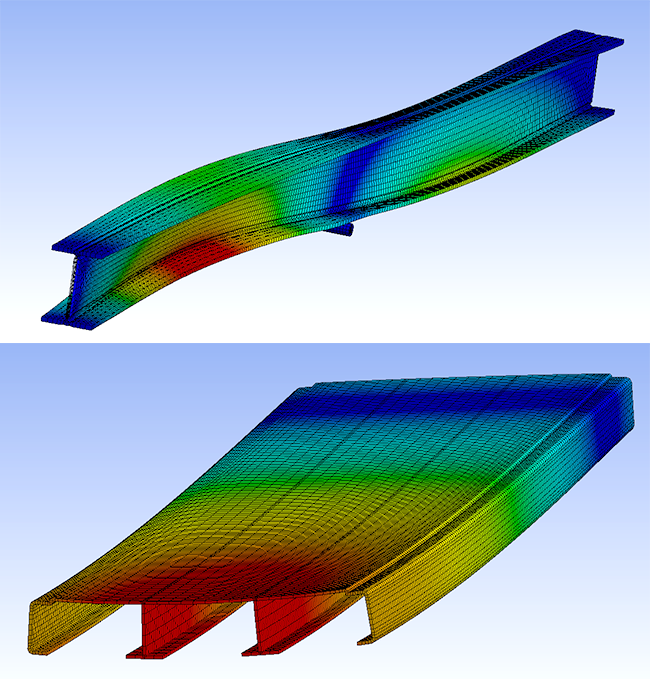

We always consider combinations of these load factors when it comes to general structural design with FRP products. Our industry-leading pultrusion process involves a dynamic series of quality assurance and control processes to ensure maximum load-bearing performance with appropriate weight profiles. This includes a bespoke composites analysis step using in-house generated lamina data via the finite element method (FEM) and classical laminated plate theory.

This in-depth mathematical and mechanical testing process is central to the success of Strongwell FRP products in a range of challenging application areas. If you would like to learn more about meeting ASCE 7 standards, simply contact a member of the Strongwell team today.

References: