Employees Learn about A3 Problem Solving

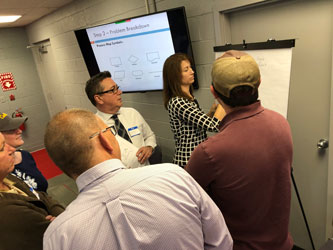

To further implement the initiative of continuous learning, Strongwell recently invited the Manufacturing Technology Center (MTC) to introduce its operations and production group to the concept of A3 Problem Solving.

To further implement the initiative of continuous learning, Strongwell recently invited the Manufacturing Technology Center (MTC) to introduce its operations and production group to the concept of A3 Problem Solving.

The A3 format was named after a commonly used paper size in Europe (297mm x 420mm, approximately 11.7”x 16.5”) and was adopted by Toyota as a one page document for proposals, statuses, and problem solving reports. For decades, manufacturers, healthcare organizations, and financial sectors have been utilizing an A3 report to provide a visual impact communication tool to monitor and achieve better outcomes.

Over two days, Shawn Wildman, MTC Senior Project Engineer, introduced over 20 employees in Bristol and Chatfield to  the seven steps within the A3 Thinking Process. The steps are:

the seven steps within the A3 Thinking Process. The steps are:

• Define the problem

• Current Conditions

• Targets

• Analysis

• Countermeasures

• Plan

• Follow-Up

In addition to classroom instruction, employees were also challenged in making their own workflows for the “Assembly of a Peanut Butter and Jelly Sandwich.” Outside of workflow designs, participants had to solve a manufacturing simulation through root cause analysis on what was causing packaging defects within a food processing facility.

Strongwell would like to thank Mr. Wildman for sharing his deep A3 knowledge, data evaluation tools, and class learning exercises to help the employees of Strongwell make it strong, make it well, and then do it better.