How Does Fiberglass Grating Hold Up Under Concentrated Loads?

Floor grating is often used in place of flat surfaces for industrial applications or where flooring is subject to severe corrosion. It is most commonly associated with raised bridges and catwalks, but grating composed of parallel bars of reinforced plastic are used for recreational water parks around the world. Each of these areas is associated with high volumes of pedestrian and worker traffic, necessitating a good degree of strength to resist deformation and potential failure.

Aluminium and steel are standout structural materials for commercial and industrial settings, owing to their non-corrosivity and generally good resistance to various loading forces. However, when factoring in weight as well as strength, slip resistance, impact resistance, plus overall response to static and dynamic loads, fiberglass grating is clearly superior.

Load Resistance of Fiberglass Gratings

A load is any static or dynamic force applied to a structural element which may cause it to deform plastically or irreversibly. Construction loads define the weight of materials that may act on the structural framework; the weight of pedestrian foot traffic on a bridge, for instance. Fiberglass grating is designed with good all-round load resistance owing to two key factors: the inherent strength of fibre reinforced plastics (FRP) combined with configuration of both parallel bar and mesh grating components.

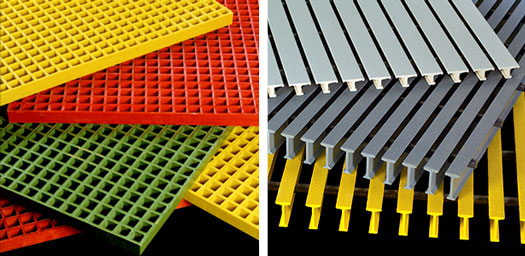

DURAGRATE® fiberglass grating is a molded mesh flooring option with bidirectional load bearing, which means applied loads are distributed multi-directionally through perpendicular bearings. DURADEK® systems, meanwhile, are comprised of parallel pultruded bars connected by high-strength cross-rods for good overall stability. Each configuration offers a high uniform load-resistance solution for both commercial and industrial flooring applications. But how do fiberglass gratings hold up under more complex loading phenomena?

What is a Concentrated Load?

Unlike a distributed load which acts upon a comparatively large cross-sectional area, concentrated loads are focused upon a very small section of a structure’s surface. Although a concentrated load is sometimes described as that which acts on a single point, realistically, all loads are applied over an area—however finite. So a concentrated load is defined as a loading stressor acting on a sufficiently small area.

In fiberglass grating design, the two key factors of concentrated loads are magnitude and location. How severe is the force and where will it be applied? High concentrated loads can cause grating cross-sections to bend or deflect, which is in turn determined by various material properties and structure.

So, to summarise, fiberglass grating performs extremely well under concentrated loads and can be carefully engineered for even greater performance under more strenuous conditions, such as industrial flooring designed to handle heavy wheel traffic.

Fiberglass Gratings from Strongwell

Would you like to learn more? At Strongwell, we provide a range of resources and detailed design brochures to help you select the right fiberglass solution for your application. Contact a member of the team today with any questions about our fiberglass grating solutions.