How and Why are Thermoset Resins used in Pultrusion?

Thermoset resins are an essential component in pultrusion manufacturing of composite parts. In their most basic sense: thermoset resins are liquefied polymers that irreversibly harden via curing. The introduction of thermal energy, ultraviolet (UV), or radio frequency (RF) waves causes separate polymer chains within the resin to undergo cross-linking reactions that produce a polymer network that is both infusible and insoluble.

Cross-linking is characterized by the formation of covalent bonds between distinct polymer chains in a thermoset resin. This depends on a range of factors, including the nature and distribution of monomers throughout the resin and the unique crosslinking mechanism. Fortunately, the various acrylics, epoxies, phenolics, and other thermoset resins used in pultrusion have been characterized in sufficient detail to guarantee the homogeneity of the polymer network in a cured composite part.

In this blog post, Strongwell will outline how and why thermoset resins are used in pultrusion in greater depth.

How are Thermoset Resins Used?

Fiber reinforced composite (FRP) materials are manufactured by impregnating glass-reinforced textiles with a high-performance thermoset resin and curing the combined materials following a formation stage.

In a typical pultrusion process: mat creels position the textile where it can be fed into the reinforcement guide. The textile is then drawn through a resin bath where it is subjected to a “wet-out” process. This bath contains the thermoset resin with any additional fillers, pigments, or catalysts needed to accelerate cross-linking during the curing phase. The textile becomes completely saturated by this resin mixture before passing through a constrictive preformer. This is essential for optimally positioning and organizing the reinforcements in the near-net shape while removing any excess liquid from the impregnator before it passes through the curing die.

Cross-linking initiates when the thermoset resin is heat activated, generally by electrical induction, or by a radio frequency (RF) wave generator. The energy supplied by these instruments causes the thermoset resin to cure with the reinforcing elements embedded within. It is then cooled and cut to appropriate lengths.

Why are Thermoset Resins Used?

Thermoset resins are used primarily to impart structural and thermal stability to the composite part, but standard resin systems can be readily modified to achieve desired characteristics. Although pultruded polymer composites are impervious to melting, they may still be subject to deformation or combustion at elevated temperatures. Various phenolics are used to increase the temperature resistance of polymer composites and improve their fire performance for demanding applications. Different thermoset resins are prescribed depending on the application area and customer specifications of custom parts.

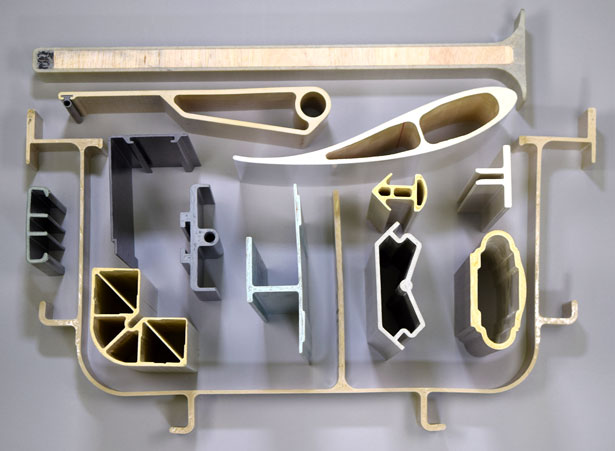

Custom Pultrusions from Strongwell

Strongwell is a world leader in pultrusion technology and custom composite manufacturing. We offer a range of standard and proprietary thermoset resin mixtures designed for a range of established industry challenges.

If you would like to learn more about the thermoset resins available for pultrusion with Strongwell, simply contact a member of the team today.