Strongwell Implements Rapid Prototyping

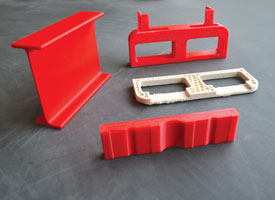

Strongwell’s on-site 10,000 sq. ft. laboratory is now equipped with a Makerbot Replicator Z18 3D replicator. Research and development is vital to the company’s future, and reliable material property data is necessary for design and development. The Makerbot Replicator Z18 replicator will produce accurate parts needed for application testing, product development, and materials research. This addition to Strongwell’s R & D department will provide physical custom-shaped models and partial assemblies to couple with drawings, creating better user experiences with new composites. Future developments with this technology will allow Strongwell to create components of machine setups and prototype experimental tooling. Traditionally these tasks have taken days to weeks to accomplish, now these elements can be manufactured within hours.

Strongwell’s on-site 10,000 sq. ft. laboratory is now equipped with a Makerbot Replicator Z18 3D replicator. Research and development is vital to the company’s future, and reliable material property data is necessary for design and development. The Makerbot Replicator Z18 replicator will produce accurate parts needed for application testing, product development, and materials research. This addition to Strongwell’s R & D department will provide physical custom-shaped models and partial assemblies to couple with drawings, creating better user experiences with new composites. Future developments with this technology will allow Strongwell to create components of machine setups and prototype experimental tooling. Traditionally these tasks have taken days to weeks to accomplish, now these elements can be manufactured within hours.

The Makerbox Replicator Z18 offers a large industrial build size, heated chamber, options to utilize multiple colors of PLA (polyactide) filament, and user friendly software which will convert CAD models into code for the printer. It has almost 2,600 cubic inches of build volume for custom and sectional test applications. The ability to print at a 100 micron resolution allows the printer to produce a smooth-to-the-touch surface which doesn’t require sanding, finishing or post- production.

This new machine can help significantly shorten inception to market cycles due to prototype development being the most time consuming portion of product launches. Strongwell has always created value for customers by offering the capability to develop, test and build in-house.