Custom Products

What Do We Mean By "Custom Pultrusions"?

A custom pultrusion is a pultruded product customized in one or more of the following ways to meet a customer's specific requirements:

- Shape: Virtually any constant cross-section part can be pultruded.

- Resin Matrix: Standard resin systems can be modified or special resins used to address such needs as elevated temperatures or special environments. Typical resins include polyesters, vinyl esters, epoxies, phenolics, urethanes and blend.

- Reinforcements: Typical reinforcements are fiberglass or carbon fibers in multi-filament strands, mat, woven fabrics or stitched fabric. Other reinforcement types and forms are possible.

- Composite Design: The selection of the resin mix, the type and form of reinforcements, and the placement of reinforcements within the composite are all ways a composite design can be customized.

Custom pultrusions contrast with standard "off-the-shelf" pultruded products in which all of the above elements are pre-established.

Why Choose Strongwell for Custom Pultrusions?

- Quality: All Strongwell pultrusion facilities operate under strict quality programs, are focused on continuous improvement and are ISO-9001 certified.

- Capability: Large parts or small, thick or thin, complex or simple, glass or carbon reinforcements (or both) - if it can be pultruded, we can do it! Strongwell has been pultruding custom shapes since 1956.

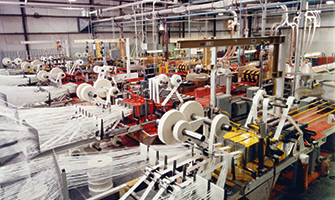

- Capacity: More than 60 machines and the ability to expand quickly assure manufacturing flexibility and no capacity constraints.

- Structural/Mechanical Engineering: Strongwell has multiple registered professional structural engineers on-staff to help you design a part, system of parts, or structure that utilizes custom pultruded components. Strongwell utilizes both mechanical and structural CAD detailing. Finite Element Analysis (FEA) is used when appropriate.

- Chemical/Process/Composites Engineering: Strongwell has experienced engineers to help you tailor the reinforcement design and resin system to meet your requirements - and to advise you how to optimize the part for low cost production.

- Laboratory: All Strongwell pultrusion facilities operate under strict quality programs, are focused on continuous improvement and are ISO-9001 certified.

- Machine and Tooling Design and Construction: Large parts or small, thick or thin, complex or simple, glass or carbon reinforcements (or both) - if it can be pultruded, we can do it! Strongwell has been pultruding custom shapes since 1956.

Product Range

|

Large to SmallStrongwell produces very large parts to very small parts. Parts can be produced in any transportable length. |

|

Thick to ThinStrongwell can manufacture thin-walled profiles with wall thicknesses under .070" (1.78 mm). Parts can also be as thick as 2" (50.8 mm) or more. |

|

Complex to SimplePultrusions range from multi-cavity, thin-walled, close tolerance parts to simple strips, angles or tubes. |

|

CoresCore materials include aluminum or steel, foam, wood, polyethylene and others. |

What Information Is Needed for a Custom Pultrusion?

A significant amount of information is needed to properly design and quote a custom pultrusion. We suggest you begin by using our Custom Pultrusion Form as a reference.

Custom Product Example

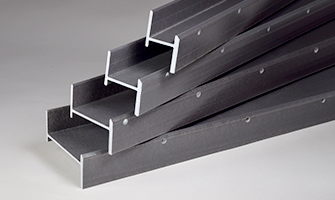

STRONGIRT® is the ideal continuous insulation (CI) cladding attachment support system. This all-FRP (fiberglass) pultruded composite uses a custom fire-retardant resin system and unique laminate design to offer superior pull out strength, excellent thermal efficiency, and the ability to work with any non-proprietary insulation (no routing or fabricating of rigid insulation is required). The product has been engineered for strength and stiffness to support cladding, insulation, and wind loads, while offering a simple, durable, cost effective solution for installers.

STRONGIRT® is the ideal continuous insulation (CI) cladding attachment support system. This all-FRP (fiberglass) pultruded composite uses a custom fire-retardant resin system and unique laminate design to offer superior pull out strength, excellent thermal efficiency, and the ability to work with any non-proprietary insulation (no routing or fabricating of rigid insulation is required). The product has been engineered for strength and stiffness to support cladding, insulation, and wind loads, while offering a simple, durable, cost effective solution for installers.

Click here to learn more about STRONGIRT®.