Case Study: Composite Pilings Protect Platinum Leed Site from Flooding

In 2011, Sacramento Municipal Utility District (SMUD) began construction on its East Campus Operations Center, a net zero Platinum LEED® energy site containing a five-story office building, fuel and storage areas, maintenance space, shops and felt parking. Platinum LEED® (Leadership in Energy and Environmental Design) designation is the highest issued by the U.S. Green Building Council.

In 2011, Sacramento Municipal Utility District (SMUD) began construction on its East Campus Operations Center, a net zero Platinum LEED® energy site containing a five-story office building, fuel and storage areas, maintenance space, shops and felt parking. Platinum LEED® (Leadership in Energy and Environmental Design) designation is the highest issued by the U.S. Green Building Council.

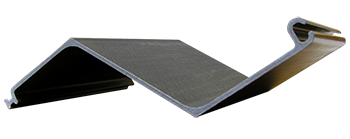

The worksite, prior to construction, was located in a flood risk area and required a flood wall. SMUD and the project’s engineers, Bohler Engineering, wanted a versatile solution which was noncorrosive, possessed an extended life cycle and reduced carbon footprint while contributing to the site’s durability. The product they selected was CMI’S UltraComposite™ UC 95 profile sheet piling.

| TECHNICAL DATA |

|---|

| Product: UltraComposite™ UC 95 Sheet Piling |

| Process: Pultrusion |

| Materials: Sheet Piling |

| Sizes: Length of 30' |

| For: Crane Materials International |

| User: Sacramento Municipal Utility District |

Installation Contractor Blue Iron, Inc. utilized sheets which were 30 feet in length. A medium weight excavator with a vibratory hammer was responsible for the driving of 100 feet of wall length daily into the rocky and challenging soil at depths of 17 feet with 13 feet exposed for flood protection.

CMI’s UltraComposite™ UC 95 profile sheet piling was manufactured in Strongwell’s ISO 9001 certified manufacturing facility to ensure consistent high quality, design strength, durability and cost. By using UC 95, CMI was able to reduce both product and installation costs while generating further interest in the utilization of American-made composite sheet piling.