Case Study: Diving in with Fiberglass

Located in Saskatchewan, Canada, the Shaw Centre serves as a community leisure facility adjoined by a public and private high school. As it is completely enclosed, the facility offers its community year-round access to competition level pools, aquatics areas, fitness rooms, and supplemental workout areas.

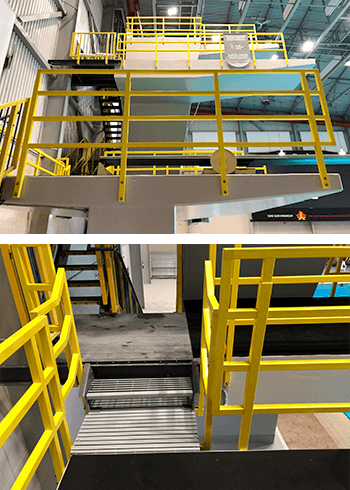

Recently, the steel handrail and baseplates in the diving deck area needed to be replaced with a more durable and corrosion resistant material. ICON Construction worked with the engineer of record to fulfill the design and specification guidelines as established by Part 4 of the National Building Code of Canada.

The chosen solution was to replace the previous handrail with a standard square 2" SAFRAIL™ system with a specialized design consideration. Each post was slightly modified to include an additional square tube and plug addition.

| TECHNICAL DATA |

|---|

| Product: Multi-Story Diving Deck Railing and Stair Structure |

| Process: Pultrusion, Fabrication |

Materials & Sizes:

|

| For: ICON Construction Ltd. |

| User: City of Saskatoon, Saskatchewan, Canada |

To connect the multiple diving decks, an erected FRP structure with access ways and landings on multiple levels was also designed out of Strongwell’s FRP products. The supporting components of the structure were constructed out of EXTREN® Structural Shapes and Plate. For stair treads, DURAGRID® I-6000 pultruded grating panels were used with a 2" deep nosing on the leading edge to ensure additional slip resistance.

On each of the landings, T-1800 DURAGRID® pultruded grating panels were chosen due to span, weight, and open space guidelines. This particular series of T-shaped bar grating offers 18 percent open space while weighing only 2.6 lbs. per square foot.

All of the aforementioned FRP structures were mechanically fastened with Grade 2205 stainless steel anchors and fasteners. Furthermore, ICON Construction’s ability to provide on-site fabrication and assembly of the FRP materials reduced the facility’s operational downtime.

The project was completed in August of 2020 and was met with positive reviews regarding construction, installation, aesthetics, and performance.