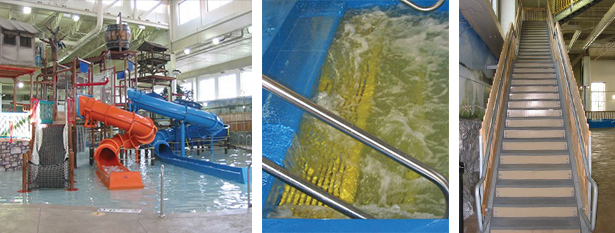

Case Study: DURAGRID® Pultruded Grating Makes a Spash at Waterpark of America

The Waterpark of America in Bloomington, Minnesota, was outfitted with Strongwell’s pultruded fiberglass grating, stair treads and stair tread risers.

The Waterpark of America in Bloomington, Minnesota, was outfitted with Strongwell’s pultruded fiberglass grating, stair treads and stair tread risers.

The new waterpark features a number of platforms and stair towers that are constantly exposed to chlorinated water, so the use of a corrosion resistant material was a must in order to maintain an attractive appearance and reduce maintenance. Strongwell’s pultruded fiberglass products met the waterpark’s needs perfectly.

Strongwell’s DURAGRID® pultruded fiberglass grating and stair treads were selected by the waterpark’s owner based upon experience using the materials in a previous application. DURAGRID® I-4000 1-1/2” pultruded grating was installed to serve as flooring on several platforms and 5’ wide DURAGRID® stair treads were used on staircases throughout the waterpark. EXTREN® 3/16” thick fiberglass plate was also used on the staircases to close the risers.

| TECHNICAL DATA |

|---|

| Product: Waterpark Platforms and Stair Towers |

| Process: Pultrusion |

Materials:

|

Sizes:

|

| For: Adolfson & Peterson |

| User: Waterpark of America, Minnesota |

In addition to corrosion resistance, Strongwell’s materials also provided much-needed skid resistance. The grating and stair treads feature a fine grit surface that provides a safe, skid resistant walking surface in wet conditions. The open construction of the grating and stair treads also allows water to drain through, eliminating pools of standing water on the walking surfaces.

“The waterpark environment is highly corrosive and metal just would not have worked,” said Troy Fountain of ESG Architectural, the Minneapolis-based architectural firm in charge of the waterpark’s design. “It was the right solution to use the open fiberglass grating and stair treads.”