Case Study: EXTREN® – Material of Choice to Support Heavy Duty Wastewater Piping

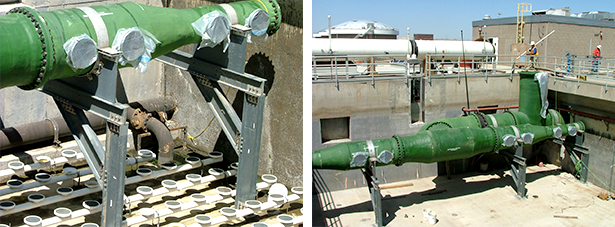

Massive aeration pipes at the Littleton/Englewood wastewater treatment plant in Englewood, Colorado, are being supported by EXTREN®, Strongwell’s proprietary line of fiberglass reinforced structural shapes.

Massive aeration pipes at the Littleton/Englewood wastewater treatment plant in Englewood, Colorado, are being supported by EXTREN®, Strongwell’s proprietary line of fiberglass reinforced structural shapes.

The cities of Littleton and Englewood, Colorado experienced major population growth that, with an increase in demand and arrival of more stringent pollution control regulations, pressed the cities to update their shared water treatment facility. Contractor Western Summit Constructors won the job to increase the wastewater treatment’s capacity from 36 million gallons per day to 50 million gallons per day.

| TECHNICAL DATA |

|---|

| Product: Wastewater Pipe Supports |

| Process: Pultrusion, Fiberglass Fabrication |

| Materials: EXTREN® 525 series fiberglass reinforced polyester, fire retardant |

Sizes:

|

| For: Littleton/Englewood Wastewater Treatment - Englewood, CO |

A portion of the plant’s expansion included the addition of 20” to 48” diameter aeration piping placed into a submerged basin. The heavy duty piping was fabricated to contain 5,000 pounds of thrust that is produced by the air passing though the aeration system. Given the corrosive wastewater treatment environment, Strongwell’s EXTREN® fiberglass structural shapes were selected to fabricate the single and dual seated pipe supports.

The EXTREN® pipe supports were a perfect fit because the lightweight FRP beams, columns and gusset plates are all corrosion resistant and extremely cost effective when compared to stainless steel. The project managers at the Littleton/Englewood were extremely pleased with the installation and love the fact that the fiberglass pipe supports will remain virtually maintenance-free for years to come!