Case Study: EXTREN® puts the “Clean” in Cleanroom

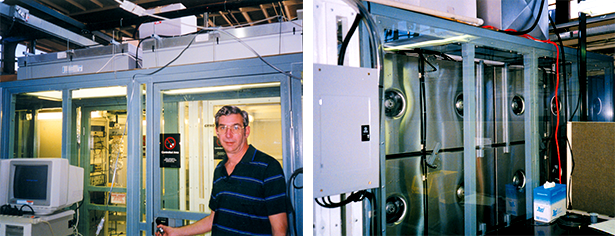

Scientists at Stanford University assembled a satellite called Gravity Probe B which was scheduled to be carried into space in 1994 onboard the Space Shuttle. Once functional, the satellite was used to test Einstein's Theory of Relativity. This immensely complicated and delicate machine was assembled in a portable cleanroom fabricated from EXTREN® Series 525 structural shapes for the superstructure and acrylic plate for the walls.

Scientists at Stanford University assembled a satellite called Gravity Probe B which was scheduled to be carried into space in 1994 onboard the Space Shuttle. Once functional, the satellite was used to test Einstein's Theory of Relativity. This immensely complicated and delicate machine was assembled in a portable cleanroom fabricated from EXTREN® Series 525 structural shapes for the superstructure and acrylic plate for the walls.

Class 10 Technologies lnc., of San Jose, California, a company specializing in cleanroom equipment and certification, selected EXTREN® for this application. According to Class 10 Technologies, EXTREN® exceeds Class 1 Cleanroom Certification Standards and was ideal for this application in all respects.

Materials had to be lightweight, easy to assemble, corrosion resistant and non-conductive. Often, modular cleanrooms of this type are broken down and moved to different locations and in some cases the entire structure must be lifted and transported. EXTREN® weighs 80% less than steel and 30% less than aluminum, can be assembled with simple craftsman tools and does not require welding.

| TECHNICAL DATA |

|---|

| Product: Cleanroom Structure |

| Process: Pultrusion |

| Materials: EXTREN® Series 525 fiberglass reinforced polyester, fire retardant |

| Sizes: 7' high L-shaped room: 9' x 12' and 15' x 4'

EXTREN® structural shapes:

|

| For: Ryan Herco |

| User: Stanford University |

| Fabricator: Class 10 Technologies |

EXTREN® is resistant to corrosion and can be cleaned with chemicals without the worry of oxidation or deterioration of its surface. Also, since EXTREN® fiberglass reinforced structural shapes are fully cured, there is no off-gassing.

Standard EXTREN® products are non-magnetic and non- conductive. When working on Gravity Probe B, these features were desirable because small amounts of static electricity build- up on the EXTREN® structure could actually pull particulates out of the air, making the room an even cleaner environment. For those situations where it is necessary that the structure be grounded, as is the case when manufacturing some electronic equipment, special conductive coating or reinforcements can be used.