Case Study: Pultruded Stairs Eliminate Corrosion Cycle for Oceanfront Lodging

The Isle of Palms is a small barrier island located 20 miles from Charleston, South Carolina. Within the island resides Seaside Inn, a small oceanfront lodge with prime beach access. The lodge’s main lobby area is located on the first floor, which is 12 ft. above ground level. For years, the access stairs to the lobby were concrete and metal, which continually rusted. Eventually, the stairs deteriorated beyond repair. The management company reported that it spent over $2,500 annually to have the stairs sandblasted, rust treated, and repainted. The overall annual process would create inaccessibility of almost two weeks with no significant improvement to aesthetics. Rust began to quickly reappear within 60 days of treatment.

The Isle of Palms is a small barrier island located 20 miles from Charleston, South Carolina. Within the island resides Seaside Inn, a small oceanfront lodge with prime beach access. The lodge’s main lobby area is located on the first floor, which is 12 ft. above ground level. For years, the access stairs to the lobby were concrete and metal, which continually rusted. Eventually, the stairs deteriorated beyond repair. The management company reported that it spent over $2,500 annually to have the stairs sandblasted, rust treated, and repainted. The overall annual process would create inaccessibility of almost two weeks with no significant improvement to aesthetics. Rust began to quickly reappear within 60 days of treatment.

To further complicate accessibility, the front staircase measured 54" wide and shared the same corrosion cycle as the 8' wide access stairs to the service elevators adjacent to the front of the facility.

The associated ongoing corrosion costs began to worry the lodge’s HOA board. The intuitive board began to look at ownership costs over a 15-year period. They calculated that almost $20,000 of maintenance expenses ($12,100 for 11 years of painting and $7,500 for three years of sand blasting treatment/repaint) had been spent on the stairs.

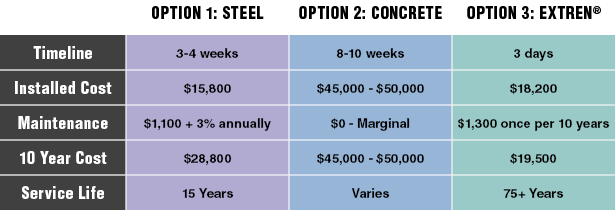

Under the advisement of a structural engineer and several general contractors, the board was presented with three viable options for replacement. Below is a summary of those three options.

As the HOA examined option 3, they realized that preserving aesthetics was key to the facility. They were surprised by EXTREN®’s ability to provide 75 years or more of life expectancy. This option also provided the lowest 10-year overall ownership costs compared to steel (32% less) and cast-in-place concrete (57% less). Additionally, the location of the inn is adjacent to a busy two-lane street which is the only access point for deliveries and tourists.

As the HOA examined option 3, they realized that preserving aesthetics was key to the facility. They were surprised by EXTREN®’s ability to provide 75 years or more of life expectancy. This option also provided the lowest 10-year overall ownership costs compared to steel (32% less) and cast-in-place concrete (57% less). Additionally, the location of the inn is adjacent to a busy two-lane street which is the only access point for deliveries and tourists.

| TECHNICAL DATA |

|---|

| Product: Oceanfront Lodge Entry Stair System |

| Process: Pultrusion |

| Materials & Sizes: EXTREN® Series 525 Structural Shapes |

| For: SRH Corporation |

| User: Seaside Inn |

As the stairs remain one of two access points for check-ins, option 3 also provided a significant reduction in downtime compared to steel (88%) and cast-in-place concrete (98%) without the need for special permits or traffic rerouting.

After 11 years of continuous use, engineers and guests still have to be persuaded that the steps are pultruded fiberglass. Based on the success of this project, the HOA voted to replace the property’s 8' wide elevator access stairs with EXTREN® as well.