Custom Pultruded CFRP Beam Lightens Fifth Wheel Design

Strongwell recently pultruded a custom CFRP beam for use in the core of JOST International’s fifth wheel system. The customer searched for a critical component improvement to reduce overall transportation costs while reducing its environmental footprint on shipping, installation, and road performance.

Designed for safety, the beam weighs in at under 2 lbs. and sees no loads during normal operations. The beam comes into action in the event of an overturn. In the moment that event occurs, the composite-steel hybrid wheel first combats plastic deformation through load absorption and then redirects external physical forces back into the locking mechanism.

Designers utilized composite’s superior strength-to-weight ratio to remove 70 lbs. of weight over the previous steel design. Integrating carbon fiber into this part also improved the cross-section strength by 50% compared to other alternative options.

| TECHNICAL DATA |

|---|

| Product: Custom CFRP Fifth Wheel Safety Beam |

| Process: Pultrusion |

| Materials & Sizes: Carbon Fiber rectangular bar |

| For: JOST International |

The new weight savings combined with JOST’s stationary mounts makes this system the world’s lightest fifth wheel rated for 55,000 lbs. This product was awarded the “Infinite Possibility for Market Growth” ACE Award in 2022; it challenges a fragmented sector of industry slower to adopt new technologies and materials due to logistical, environmental, and financial headwinds.

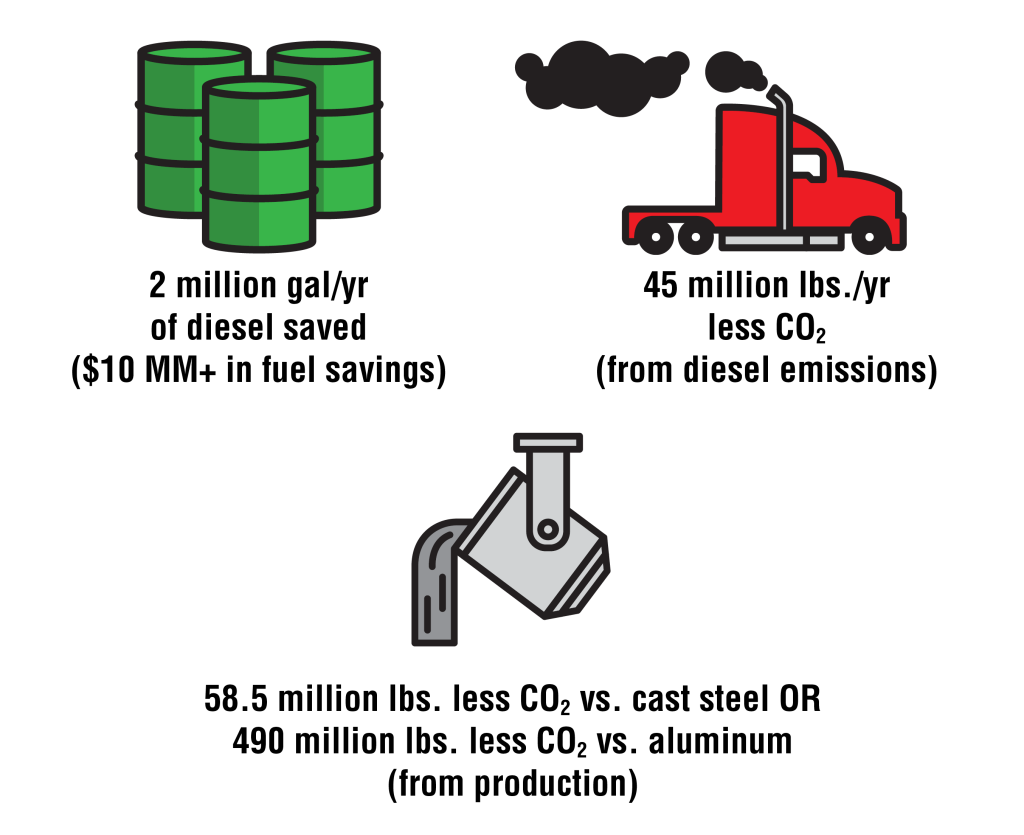

Implementing this design on the 250,000 qualified trucks estimated for 2023 production alone would result in: