Phenolic Resin Products for the Oil and Gas Industry

Phenolic resins are a group of thermosetting polymers with advanced thermal stabilities and improved chemical resistances over other synthetic polymers. They are vastly flexible, and have been used in the production and manufacture of an enormous range of molded products. The first commercially available plastics were formulated using phenolic resins, and they have been used throughout history to produce telephones, worksurfaces, adhesives, circuit boards, and more.

Many of the conventional commercial applications of phenolic resins have been supplanted by other materials, but it has been increasingly utilized in the industrial sector due to its elevated temperature-resistant properties.

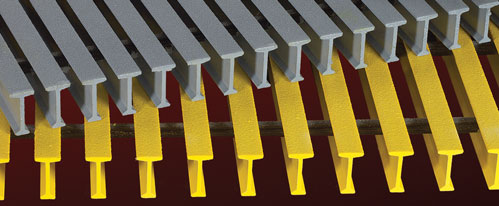

Multiple layers of phenolic resins are applied to high-strength fiberglass products, saturating the substrate and creating a bound laminate surface that is fully-cured during a heat treatment process. This is known as a thermoset polymer matrix, or a resin matrix, and is designed to elevate the resistant-qualities of a product for stringent applications. The primary benefit of industrial phenolic resin products is their advanced temperature resistance, corrosion resistance, and improved mechanical stability. This manifold offers distinct advantages for the petrochemical sector, which requires structural materials capable of withstanding high temperatures and potential outbreaks of fire.

Read More: Pultrusion: Resin Systems and Flame Retardancy

One of the most popular uses of a phenolic resin matrix is for the formation of phenolic grating for oil and gas processing facilities – particularly for offshore applications. Marine oil rigs are extraordinary structures designed to extremely stringent specifications. Platforms are required to float on tension legs, and to resist the constant corrosiveness and abrasiveness of saltwater and tidal forces. They must also be certified to multiple health and safety requirements, with excellent fire resistance and reduced thermal conductivity in the unlikely event of fuel combustion.

Phenolic Resin Grating

DURAGRID® phenolic grating is the ideal replacement for conventional materials in offshore applications, due to its comprehensively advanced resistant properties and reduced smoke / fume emissions. It is also as much as three times lighter than comparative steel grating products, weighing approximately 3.5 lb/ft2. The expansive improvements offered by phenolic resin enhanced fiberglass products have the potential to reduce offshore rig construction costs by as much as 25%, including reduced maintenance costs and downtimes due to the noncorrosive nature of DURAGRID® phenolic.

Phenolic Resin Railings

SAFRAIL™ handrails are designed to support the excellent mechanical stability of phenolic grating, with specifications of rounded, squared, and channel-top rail systems reinforced with phenolic resins. These products work together, introducing multiple structural advancements to help establish reinforced fiberglass products as a new industry standard for oil and gas applications.

Phenolic Resin Structural Shapes and Plates

EXTREN® structural shapes and plates are manufactured using three different resin systems for standard specifications. These do not include phenolic resins, however, Strongwell does offer custom pultrusion services that enable high-strength structural components with phenolic matrixes. These products can be formulated from E-Glass and reinforced carbon materials, providing improved fire retardancy and reduced smoke emissions for oil and gas facility materials.

Phenolic Resin Products from Strongwell

Strongwell is a leading developer of fiberglass products for a broad range of industries, providing unique solutions to bespoke customer applications and requirements.

If you would like any more information about our phenolic resin products, please do not hesitate to contact us.