Strongwell’s Fiberglass Armor Exceeds Ballistic Specifications

Strongwell’s HS Armor panels were initially designed for the U.S. military. The panels provided overhead protection for troops stationed in Iraq. Since then, Strongwell has advanced the ballistic panel technology to include a wider range of armor types.

Strongwell’s HS Armor panels were initially designed for the U.S. military. The panels provided overhead protection for troops stationed in Iraq. Since then, Strongwell has advanced the ballistic panel technology to include a wider range of armor types.

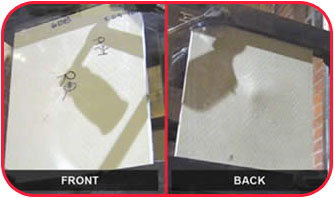

Designed for ballistic resistance, the HS Armor panels are assembled using specially constructed glass reinforcements in a proprietary resin matrix. The panel components are then cured in a controlled cycle. When a projectile strikes the composite armor, the panel delaminates in a way that absorbs the energy and stops the projectile.

HS Armor panels are independently tested on a regular basis to ensure conformance to specification requirements. The fiberglass composite panels have exceeded UL 752 levels 1 through 3 and NIJ (National Institute of Justice) Levels 1, 2A, 2 and 3A. HS Armor has also been tested against storm damage. States such as Florida require 3/4” plywood to withstand a direct hit from a flying 2” x 4”, traveling at 39 m.p.h. A 1/8” HS Armor panel has been shown to deflect the beam at speeds exceeding 80 m.p.h.

The corrosion resistant properties of the fiberglass ballistic panels ensure less maintenance and a longer product life than steel alternatives. The lightweight armor panels are easy to fabricate using ordinary carpenter’s tools. Installation of panels can be accomplished with bolts, screws or industrial grade adhesive. For more information about the armor panels, download the HS Armor Panels Flyer or visit the Composite Armor section of the website.