Understanding the Properties and Applications of Phenolic Resin in Fiberglass Structures

Phenolic resin is commonly used to manufacture fiberglass structures in several industries, where outstanding levels of chemical and temperature-resistance are required to ensure optimal performance. In this blog post, we will look at the chemical composition, mechanical properties, and some applications of phenolic resin, with a focus on its use in the gas and oil industries.

Chemical Composition

Phenolic resin is a thermosetting polymer produced with a catalyst by combining phenol and formaldehyde under heat. Throughout this process, a network of permanently bonded molecules is created, which provides the resin with properties that are crucial to many industries and applications. The resulting properties of a phenolic resin can depend on which catalyst was used - and how much of it - during the process, and the most common catalysts used to produce phenolic resins include hydrochloric acid, oxalic acid, and sulfuric acid.

Mechanical Properties

Phenolic resin has many superior mechanical properties and is used globally to manufacture a wide range of molded products. It is an extremely diverse material with high heat, chemical, and moisture resistance. Other crucial properties include the following:

- Adaptable

- Dimensional stability

- Electrical resistance

- High mechanical resistance

- High strength-to-weight ratio

- High tensile strength

- Low toxicity

- Outstanding thermal stability

The above properties make phenolic resin ideal for manufacturing products designed for use in harsh environments. Combined with the right reinforcements, phenolic resin is suitable for structural components, and its high compressive strength means it will not deform under high pressure. However, it is important to mention that phenolic resins can be brittle, but this can be combatted by pairing the resin with supplementary fillers.

Applications

Over the years, phenolic resin has been used to manufacture adhesives, circuit boards, work surfaces, and more. It is frequently used in industrial applications, especially in the gas and oil industry. Some common applications of phenolic resin include manufacturing pipe insulation, composite materials, and a range of fiberglass products. Fiberglass products can be enhanced by adding multiple layers of phenolic resin, which saturates the substrate and produces a bound laminate surface. During a heat treatment process, the layers are fully cured, resulting in a thermoset polymer matrix that enhances the resistant qualities of the product.

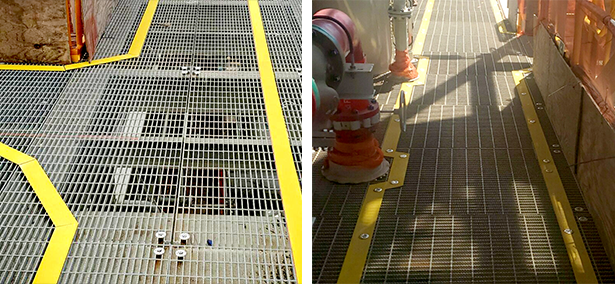

In the gas and oil industry, a phenolic resin matrix is used to manufacture resin gratings, railings, and structural shapes and plates that can be used in offshore applications and other harsh environments. Phenolic resin is the perfect solution for harsh settings because of its outstanding heat and corrosion resistant properties, reduced smoke emissions, and improved fire retardancy. They are also lightweight, making the products easier to transport and install under challenging environments.

Strongwell and our Phenolic Resin Products

Strongwell develops pultruded fiberglass products for a wide range of industries and clients worldwide and offers custom solutions for specific client applications. Our phenolic resin products are manufactured under our DURAGRID®, EXTREN®, and SAFRAIL™ brands, which include gratings, structural shapes and plates, and railings, respectively. These are highly chemically resistant, withstand high temperatures and pressures, and offer good thermal stability.

To learn more about how phenolic resin is used in the gas and oil industries or to enquire about our products, please don’t hesitate to contact Strongwell.