Composites Draw All Fanfare

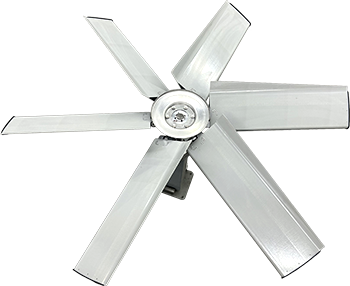

As a leading manufacturer of efficient axial flow fans since 1940, Moore Fans has been a major player and pioneer within the industrial sector as a leading provider of fans for air-cooled heat exchangers, cooling towers, and radiators.

The company offers three classes of high-efficiency fans for various air movement applications. To meet customer specifications and expand product offerings, the manufacturer looked for a composites manufacturer to supply blades offering high strength and anti-corrosion properties for certain heat exchange installations. These blades are used in fans ranging from 3 feet to 18 feet in diameter.

Since 2021, Strongwell has produced thousands of lineal feet of custom fiberglass reinforced fan blades for Moore Fans. Each blade is pultruded with a vinyl ester resin paired with a stitched mat as added reinforcement.

| TECHNICAL DATA |

|---|

| Product: Axial Flow Fan Blades |

| Process: Pultrusion |

| Materials & Sizes: Custom pultruded profile up to 6 feet in length |

| For: Moore Fans |

These fan blades have been installed throughout multiple conditions of cooling towers and air-cooled heat exchangers within challenging environments, including, but not limited to, those requiring ATEX certification.

Prior to launch, this custom pultruded profile endured thousands of hours of product testing to ensure the blades were capable of enduring high cycles of fatigue throughout a wide range of temperatures. In these temperature tests, temperatures reached up to 180 degrees F.

By offering FRP fan blades, Moore Fans was able to grow its overall industrial airflow solution market share.