Properties and Benefits of Thermoset Resins

Fiber reinforced polymers (FRP) are often described as thermoset goods, which means they have been engineered using a thermoset resin. Unlike thermoplastics, a thermoset resin does not have a defined melting point after its initial heat treatment phase. This means that shapes cannot be reformed once they have cooled. There are many benefits of this, though they vary distinctly based on the underlying properties of the resin used to construct FRP.

This blog post will explore the properties and benefits of thermoset resins in more detail.

Types of Thermoset Resins Available

Various standard and custom thermoset resin systems are available for FRP manufacturing, each of which offers unique pricing and thermochemical properties to suit distinct customer requirements. A selection of these include:

- Epoxy

- Methyl Methacrylate (MMA)

- Phenolic

- Polyester

- Polyurethane

Polyester is a good, general purpose thermoset resin for FRP manufacturing, which is typically available as orthothalic (general purpose) or isophthalic polyester (premium polyester). GP polyester resins offer adequate resistance to water and a choice of common chemicals. However, PP thermosets are preferred for applications where corrosives are of a more aggressive nature.

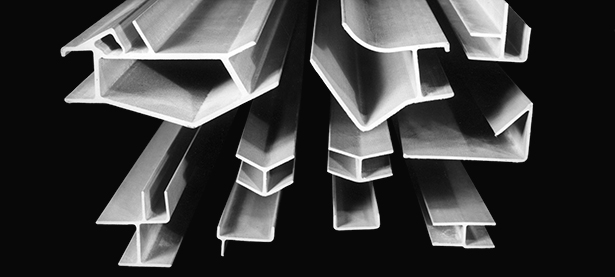

Each of these resins is used to fabricate panels, structural parts, and grating for various markets. However, they are often exceeded by vinyl ester thermoset resins when long-term structural integrity is a priority.

Outlining Vinyl Ester Resins

Vinyl ester resin is a custom thermoset solution manufactured by esterification of a suitable epoxy with either an acrylic or methacrylic acid (MMA). It offers improved long-term mechanical performance over polyester thermoset resins and a reduced price point compared to pure epoxy. It boasts superb resistance to moisture ingress and enhanced anti-corrosive properties compared to GP polyesters. As a result, vinyl ester resins are ideal for the use in marine and coastal applications.

Outlining Epoxy Thermoset Resins

Epoxies are among the most favored thermoset resins for their outstanding mechanical and thermal properties in the cured condition. Such is the thermochemical integrity of typical epoxies that they are often used for bonding and reinforcing FRP components, as well as sealing cut ends of machined parts to inhibit chemical intrusion.

MMA may be used alone for proprietary applications, but the resin is most commonly used as a precursor to poly (methyl methacrylate) (PMMA), or as an epoxy-blend in custom thermoset resin mixtures.

Outlining Polyurethane Thermoset Resins

Polyurethanes are also widely used due to their wear-resistant and load-bearing capacities. They are regularly used as both impregnating resins and thick coating materials for components that need more advanced surface veiling, as polyurethane offers a durable surface finish.

Outlining Phenolic Thermoset Resins

Phenolic resins are synthetic polymers acquired, in part, from formaldehyde. This explains their exceptional flame-retardancy and low smoke emission properties, providing the best fire resistant characteristics of all standard thermoset resins available to FRP manufacturers. If you would like to learn more about phenolic resins in action, read our previous blog post: Phenolic Resin Products for the Oil and Gas Industry.

Thermoset Resins from Strongwell