Grating

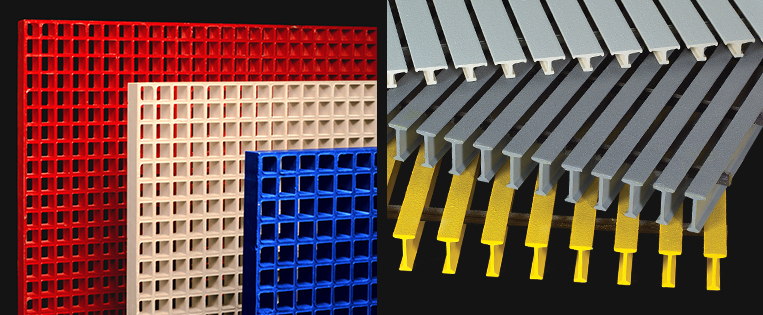

DURAGRATE® Molded Grating | DURADEK®/DURAGRID® Pultruded Grating | DURATREAD™ Stair Tread Covers

Strongwell offers both molded grating (DURAGRATE®) and pultruded grating (DURADEK® and DURAGRID®). All Strongwell gratings are made exclusively in the U.S.A.

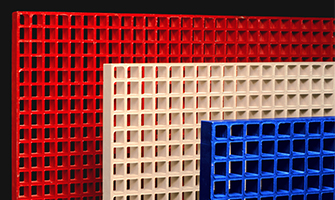

DURAGRATE® Molded Grating

DURAGRATE® molded fiberglass grating is a premium-quality mesh grating panel made exclusively in the U.S.A. While molded grating is a chemical resistant flooring choice for many industrial applications, DURAGRATE® offers performance and quality superior to imported suppliers.

DURAGRATE® molded fiberglass grating is a premium-quality mesh grating panel made exclusively in the U.S.A. While molded grating is a chemical resistant flooring choice for many industrial applications, DURAGRATE® offers performance and quality superior to imported suppliers.

Features of DURAGRATE®

- Corrosion Resistant

- Easy To Fabricate

- Fire Retardant

- Impact Resistant

- Low in Maintenance

- Low in Conductivity

- Lightweight

- Bidirectional Load Bearing

- Easy To Install

- Cost Effective

- Uniform in Appearance

- The Only Molded Grating Made Exclusively in the U.S.A.

|

Fiberglass Grating Manufacturers Council (FGMC)All DURAGRATE® molded fiberglass grating is manufactured in accordance with FGMC standards. 1" thick DURAGRATE® panels are tested to meet the mechanical properties of FGMC protocols. All DURAGRATE® panels greater than 1" thick are tested and exceed the mechanical properties of FGMC protocols. |

|

NSF InternationalDURAGRATE® can be manufactured to meet NSF-61 certification for hot and cold upon request (VE resin system only). |

|

American Bureau of ShippingApproved for use on a variety of ABS Class ships. |

|

Americans with Disabilities ActSelect DURAGRATE® panels meet ADA requirements for both mesh size (1/2" open space) and slip resistance. See the DURAGRATE® Brochure for more details. |

Accessories

A standard line of accessories is available for installing DURAGRATE® molded fiberglass grating panels. Accessories include DURAGRATE® stair treads, DURATREAD™ stair tread covers, panel hold-down clips, panel connectors, elevated floor legs, curb angle, solid surface options and sealing kits.

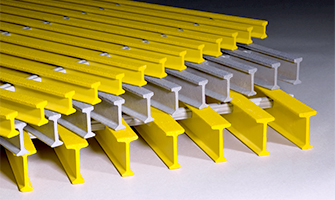

DURADEK® Pultruded Grating

DURADEK® is high strength pultruded bar grating made exclusively in the U.S.A. that can be used like traditional metal grates or fiberglass molded grating but offers the inherent benefits of pultrusion. DURADEK® is an ideal replacement for steel, aluminum, or molded fiberglass gratings anywhere frequent grating and walkway replacement costs are unacceptable.

DURADEK® is high strength pultruded bar grating made exclusively in the U.S.A. that can be used like traditional metal grates or fiberglass molded grating but offers the inherent benefits of pultrusion. DURADEK® is an ideal replacement for steel, aluminum, or molded fiberglass gratings anywhere frequent grating and walkway replacement costs are unacceptable.

DURADEK® is stocked and available with bearing bars in 1" or 1-1/2" thick I-shapes or a 2" thick T-shape. 1" and 1-1/2" thick panels can be purchased in 3'x10', 4'x8', 4'x12', 5'x10', 3'x20', 4'x20' or 5'x20' sizes. 2" thick panels can be purchased in 4'x12', 5'x10', 3'x20', 4'x20' or 5'x20' sizes. All sizes of DURADEK® grating are available with a flame retardant polyester or vinyl ester resin system with bearing bars in a light gray or yellow color. All panels offer cross-rods spaced 8" on center and are either light gray (polyester) or black (vinyl ester).

Comparing DURAGRATE® and DURADEK®

DURAGRATE® and DURADEK® are both high-quality, USA-made gratings to serve your needs. However, there are instances where one grating type (molded vs. pultruded) is a better option. Read this article to compare DURAGRATE® and DURADEK® in more depth.

DURAGRID® Custom Pultruded Grating

Like DURADEK®, DURAGRID® is high strength pultruded bar grating made exclusively in the U.S.A. Any of Strongwell's 100+ pultruded grating not part of the DURADEK® line are considered DURAGRID®. DURAGRID® offers customers the selection of bar spacing (which creates varying open space in the grating or grid), bar shape, cross-rod placement, custom fabrication, custom resin or color.

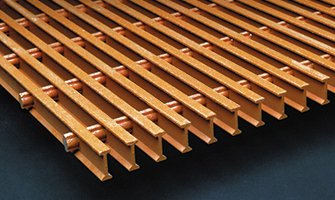

DURAGRID® HD Heavy Duty Grating

DURAGRID® HD Heavy Duty Grating is a pultruded bar type grating that can be designed and used like traditional metal grates. The solid individual bearing bars are designed to take heavy wheel traffic such as fork lifts, tow motors and truck traffic. Heavy duty grating is constructed of the same type composite used in the other DURAGRID® products.

DURAGRID® HD Heavy Duty Grating is a pultruded bar type grating that can be designed and used like traditional metal grates. The solid individual bearing bars are designed to take heavy wheel traffic such as fork lifts, tow motors and truck traffic. Heavy duty grating is constructed of the same type composite used in the other DURAGRID® products.

DURAGRID® Phenolic Grating

DURAGRID® Phenolic Grating is often used in the oil and gas industry because of its increased fire and smoke performance. DURAGRID® Phenolic is the first composite grating to receive U.S. Coast Guard approval for use in locations and applications as allowed in the ASTM F3059 Matrix guide for fiberglass grating meeting Structural Fire Integrity Level 2 (L2). The ASTM F3059 enhances and will replace the USCG PFM 2-98 matrix.

DURAGRID® Phenolic Grating is often used in the oil and gas industry because of its increased fire and smoke performance. DURAGRID® Phenolic is the first composite grating to receive U.S. Coast Guard approval for use in locations and applications as allowed in the ASTM F3059 Matrix guide for fiberglass grating meeting Structural Fire Integrity Level 2 (L2). The ASTM F3059 enhances and will replace the USCG PFM 2-98 matrix.

Phenolic Grating, compared to typical polyester, vinyl ester and epoxy FRP products, offers major improvements in reduced smoke density, reduced smoke toxicity and structural fire integrity when exposed to fire. DURAGRID® Phenolic Grating complies with Annex 1 (Resolution MSC.307(88) , Part 2, 2.41 and 2.4.2 (smoke and toxicity testing) of the FTP Code (International Code for Application of Fire Test Procedures) - (MSC 88/26/ Add.2) issued by the International Maritime Organization.

Features of DURADEK® & DURAGRID®

- Corrosion Resistant

- Structurally Strong

- High Impact and Fatigue Strength

- Lightweight

- Fire Retardant

- Easy to Fabricate and Install

- Low Maintenance

- Low Electrical and Thermal Conductivity

- Resistant to Chipping and Cracking

- Aesthetically Pleasing Appearance

- Skid Resistant

- Non-Sparking

3-Piece Cross-Rod System

Strongwell’s 3-piece cross-rod system is the best assembly method for pultruded grating in the fiberglass grating industry because it provides better stability than competitive crossrod systems. The three piece members in combination with Strongwell’s proprietary bonding method tie the bearing bars together and provide stability to the grating panel. This system makes Strongwell's pultruded grating the superior choice in the marketplace.

DURAGRID® custom grid and grating systems are designed to accommodate specific applications that cannot effectively be met by a standard fiberglass grating. DURAGRID® offers the customer options such as selection of bar spacing (which creates varying open space in the grating or grid), bar shape, cross-rod placement, custom fabrication, custom resin or color.

Fabrication

DURADEK® and DURAGRID® gratings are lightweight and, therefore, easily handled in installation, and cost less to ship than steel grating. A patented 3-piece cross-rod system mechanically locks and chemically bonds the cross-rods to the web of each bearing bar. This separates and affixes bearing bars firmly in position and distributes concentrated loads to adjacent bars. The system allows DURADEK® and DURAGRID® grating to be cut and fabricated like a solid sheet.

Standard carpenter's tools with abrasive cutting edges may be used; just coat the cut ends with resin sealer and install. You will find the detailed Field Fabrication Guide under the Literature tab at the top of this page.

Attachment Methods

Strongwell has released a Decking Fasteners flyer that provides information on the preferred fasteners available for all Strongwell decking products. Illustrations of the various fasteners and uses are exhibited on the back of the flyer.

DURATREAD™ Stair Tread Covers

DURATREAD™ molded fiberglass stair tread covers provide an easy, cost-effective way to increase the safety of stairways. The covers feature a gritted surface and are intended for installation over concrete, metal, or wood steps and for over fiberglass stair treads.